What Are You Looking For?

What Are You Looking For?

The water pump comprehensive performance test system equipment of Guangzhou Hejin Automation Control Technology Co., Ltd. (Turkey Branch) is a high-end test device designed and developed for accurately evaluating various performance indicators of water pumps. The system integrates advanced sensor technology, automatic control technology and precise data acquisition and processing algorithms, and can comprehensively and accurately measure and analyze key parameters such as flow, head, power, efficiency, etc. of water pumps, providing strong technical support and data basis for multiple links such as water pump research and development, production quality control, performance optimization and after-sales maintenance.

Item No. :

HCWP-300Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TürkiyeSupply Ability :

1 sets per 3 monthLead Time :

60 Working DaysConventional packaging :

PlywoodWater pump comprehensive performance test system

Product Introduction:

This water pump comprehensive performance test system adopts a modular design concept and has high flexibility and scalability. It can be personalized according to different types and specifications of water pumps. Whether it is a small civil pump or a large industrial pump, it can perform efficient and accurate performance tests on this system. The system operation interface is simple and intuitive, easy for operators to master, and is equipped with a complete automated test process, which can realize one-click start test, greatly improving test efficiency and reducing human errors. During the test, the system can collect and display various test data in real time. Through advanced data analysis software, the test results can also be deeply processed to generate detailed test reports, including performance curve drawing, data comparison analysis, etc., to provide users with comprehensive and intuitive water pump performance evaluation results.

Product Features:

(I) High-precision measurement

Adopting high-precision flow sensors, pressure sensors and power sensors, etc., ensures that the measurement accuracy of water pump flow, head and power reaches the industry-leading level, and the error is controlled within a very small range, providing users with reliable test data.

The sensor has good stability and repeatability, and can maintain high-precision measurement performance during long-term continuous testing, without being significantly affected by factors such as ambient temperature and humidity.

(II) Automated control

The system realizes automated test process control, from the start-up of the water pump, adjustment of operating parameters to data collection and stop testing. The entire process does not require excessive human intervention, which effectively improves the test efficiency and accuracy.

The operating point of the water pump can be automatically adjusted according to the preset test program, and the changes in parameters such as flow rate and head can be accurately controlled to realize the automatic drawing and testing of the full performance curve of the water pump, which greatly saves test time and labor costs.

(III) Multifunctional data processing

Built-in powerful data processing software can process, analyze and store a large amount of collected test data in real time. Not only can it calculate various performance indicators of the water pump, such as efficiency, cavitation margin, etc., but it can also draw performance curves such as flow-head, flow-power, flow-efficiency, etc., to intuitively display the working characteristics of the water pump.

Supports data export and backup functions, which is convenient for users to further analyze and process test data or share and integrate data with other systems. At the same time, it has a data history query function, which can be used to review previous test records at any time, facilitating long-term tracking and comparative analysis of water pump performance.

(IV) Strong compatibility

The system design has wide compatibility and can adapt to the testing needs of water pumps of different brands and models. Whether it is a centrifugal pump, axial flow pump, mixed flow pump or other special types of water pumps, you only need to set parameters and adjust the tooling to perform performance tests on this test system.

A rich communication interface is reserved, which can be seamlessly connected with external devices such as computers, printers, data storage devices, etc., to facilitate users to perform data transmission, report printing, and system expansion and upgrade.

(V) Safe and reliable

In terms of hardware design, the system uses high-quality electrical components and mechanical components, has good anti-interference ability and stability, and can operate reliably in complex industrial environments. At the same time, it is equipped with complete safety functions such as overload protection, short circuit protection and leakage protection to effectively ensure the safety of testers and equipment.

In software design, multiple authority management and fault diagnosis alarm functions are set. Operators of different levels can only perform operations with corresponding permissions to prevent misoperation from affecting test results and equipment. The system can monitor the operating status of the equipment in real time. Once a fault or abnormal situation occurs, it will immediately send out an audible and visual alarm signal and display detailed fault information, which is convenient for maintenance personnel to quickly locate and troubleshoot.

Product Advantages:

(I) Leading Technology

Relying on the profound technical accumulation and R&D strength of Guangzhou Hejin Automation Control Technology Co., Ltd. in the field of automation control, the comprehensive performance test system of the water pump adopts a number of internationally advanced technologies and patented algorithms, such as high-precision sensor calibration technology, intelligent data fusion algorithm and adaptive control strategy, etc., which makes the product have significant competitive advantages in performance indicators and test accuracy, and can meet the strict requirements of high-end customers at home and abroad for water pump test equipment.

(II) Customized Service

The company has a professional technical team that can provide customers with personalized comprehensive performance test system solutions for water pumps according to their special needs and application scenarios. Whether it is special test standards for specific industries or special customization requirements for system functions and test scopes, they can be responded to and met quickly and effectively. This customized service capability can not only help customers solve practical problems, but also enhance the competitiveness of customers' products and create greater value for customers.

(III) High-quality after-sales service

The company has established a complete after-sales service network, with professional after-sales service teams in Turkey and around the world, which can respond to customers' after-sales needs in a timely manner. Whether it is equipment installation and commissioning, operation training or fault repair and maintenance, we can provide fast, efficient and high-quality services to ensure the normal operation of customer equipment, reduce downtime and reduce customer operating costs.

Provide regular return visits to understand the use of customer equipment and customer satisfaction, and collect customer feedback and suggestions in a timely manner to continuously improve and optimize the product. At the same time, provide customers with free software upgrade services so that customers can enjoy the latest technological achievements and functional improvements, extend the service life of equipment and improve the return on investment.

Technical standards:

ISO 9906:2012 "Centrifugal pumps - Hydraulic performance acceptance tests - Grades 1 and 2"

GB/T 3216 - 2016 "Rotary power pump hydraulic performance acceptance test level 1, 2 and 3"

API 610 "Centrifugal Pumps for General Refinery Service" and other standards.

During the design, manufacturing and testing process, we ensure that the system's performance indicators and test methods meet the requirements of the above standards, and provide users with test data and reports with international credibility.

Technical parameters:

| Project | Parameters |

| Test pump type | Centrifugal pump,Mixed flow pump,Axial flow pump,Submersible pump for wells,Screw pump,Submersible pump for sewage,Small submersible pump,Fire pump |

| Voltage (V) | 0-500V |

| Power (KW) | 200 |

| Speed (r/min) | 0-3000rpm |

| Flow (M³/h) | 0-1000M³/h |

| Height (m) | 0-200m |

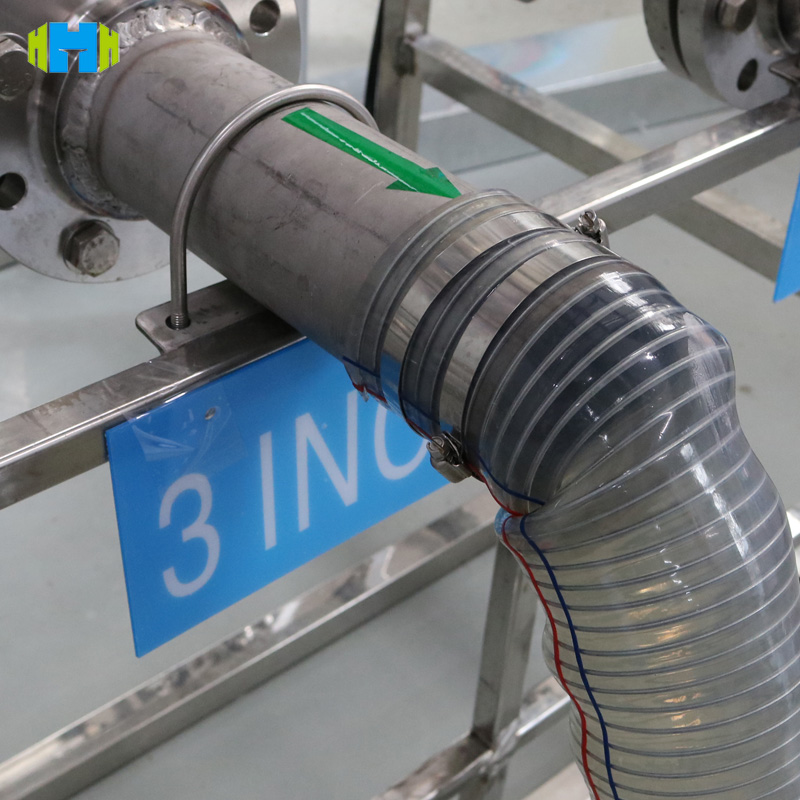

| Pipe diameter (mm) | 1 inch, 2 inches, 3 inches, 4 inches, 4 lines in total |

Application areas:

Pump manufacturing companies: In the process of pump research and development, it is used to test and optimize the performance of newly designed pumps to ensure that the product performance meets the design requirements; in the production process, as an important means of quality control, each pump is tested for performance before leaving the factory to ensure the stability and consistency of product quality.

Scientific research institutions: It is used to carry out scientific research projects related to pumps, such as performance research of new pump types, numerical simulation and experimental verification of the internal flow field of pumps, etc., to provide accurate experimental data support for scientific research work and promote the continuous innovation and development of pump technology.

Power industry: Performance testing and evaluation of various pumps in power plants, such as feed pumps, condensate pumps, circulating water pumps, etc., to promptly discover performance degradation problems in the operation of pumps, provide a basis for equipment maintenance, overhaul and energy-saving transformation, and ensure the safe and stable operation of power plants and the realization of energy-saving and consumption-reduction goals.

Petrochemical industry: It is used for performance testing and management of various process pumps, fire pumps, etc. in petrochemical plants. In the petrochemical production process, the performance of the water pump is directly related to the normal operation of the process and safe production. Through regular performance testing, the reliable operation of the water pump under complex working conditions can be ensured, production efficiency can be improved, and the risk of accidents can be reduced.

Water conservancy engineering field: In large-scale water conservancy hub projects, urban water supply systems and other projects, the performance of water pumps in various water pumping stations is tested and monitored. For example, the performance of drainage pumps and water supply pumps in pumping stations is evaluated to optimize the operation and scheduling of water pumps, improve the operation efficiency of water conservancy projects and the utilization efficiency of water resources.

Detailed picture:

FAQ:

(I) How long does it take to install and debug the system?

In general, for a standard pump comprehensive performance test system, our professional technicians will take about 60 working days to install and debug on site. However, if the customer has special site conditions or customized requirements, the installation and debugging time may be extended. The specific time will be determined in consultation with the customer based on the actual situation.

(II) What types of pumps can the system test?

This test system has strong compatibility and can test various common types of pumps, including centrifugal pumps, axial flow pumps, mixed flow pumps, deep well pumps, submersible pumps, etc. At the same time, for some pumps with special structures or special applications, such as shielded pumps and magnetic pumps, as long as appropriate tooling adjustments and test program settings are made according to the specific parameters and requirements of the pump before testing, performance tests can also be performed on this system.

(III) How is the accuracy of the test data guaranteed?

To ensure the accuracy of the test data, we use high-precision sensors and strictly calibrate and calibrate the sensors before leaving the factory. During the test, the system will also monitor and self-calibrate the working status of the sensor in real time to compensate for the impact of environmental factors on the measurement results. In addition, the system's data acquisition and processing software uses advanced algorithms, which can filter, correct errors, and verify accuracy of the collected data, further improving the reliability of the data. At the same time, our test system is designed and manufactured in strict accordance with relevant international and domestic standards. From hardware to software, it has undergone strict quality control and performance verification to ensure that users are provided with accurate and reliable test data.

(IV) What does after-sales service include?

Our after-sales service covers many aspects, including equipment installation and commissioning, operation training, fault repair, maintenance, and regular return visits. During the equipment installation and commissioning stage, our technicians will ensure that the equipment can operate normally, and provide detailed training to the customer's operators to familiarize them with the equipment's operating procedures and precautions. During the use of the equipment, if a fault occurs, customers can contact our after-sales service team at any time. We will respond as soon as possible and provide remote technical support or arrange for technicians to rush to the site for repairs. We will also provide regular equipment maintenance services according to customer needs to ensure that the equipment is always in good operating condition. In addition, we will regularly return to customers to understand the use of the equipment and customer satisfaction, and collect customer opinions and suggestions in order to continuously improve products and services.

After-sales service

Equipment installation and commissioning: The company dispatches professional technicians to the customer site to install and commission the equipment to ensure that the equipment can be put into use smoothly, and conducts on-site training for the customer's operators so that they can master the operation methods and daily maintenance points of the equipment.

Warranty service: During the equipment warranty period, the company provides free repair services for failures caused by product quality problems, including replacement of faulty parts. The warranty period is calculated from the date of qualified equipment acceptance, and the specific duration is implemented according to the contract agreement.

Maintenance response time: The company has set up a special after-sales service hotline. Customers can call the after-sales service hotline at any time when they encounter equipment failures. After receiving the customer's fault repair notice, the company's after-sales service team will respond within 72 hours, preliminarily determine the cause of the failure through telephone, remote diagnosis, etc., and provide corresponding solutions. For situations where on-site repairs are required, after-sales service personnel will rush to the customer site for repairs in the shortest time.

Regular return visits and maintenance: The company's after-sales service team will regularly return visits to customer equipment to understand the use and operating status of the equipment, provide equipment maintenance suggestions for customers, and provide regular on-site maintenance services according to customer needs, such as equipment cleaning, sensor calibration, software upgrades, etc., to ensure that the equipment always maintains a good performance state and extends the service life of the equipment.

Technical support and training: The company provides customers with lifelong technical support services. If customers encounter any technical problems during the use of the equipment, they can contact the company's technicians for help at any time. At the same time, according to customer needs and technological development, the company can provide customers with irregular technical training services to help customers improve the technical level of operators and their maintenance and management capabilities for equipment.

Hot Tags :