What Are You Looking For?

What Are You Looking For?

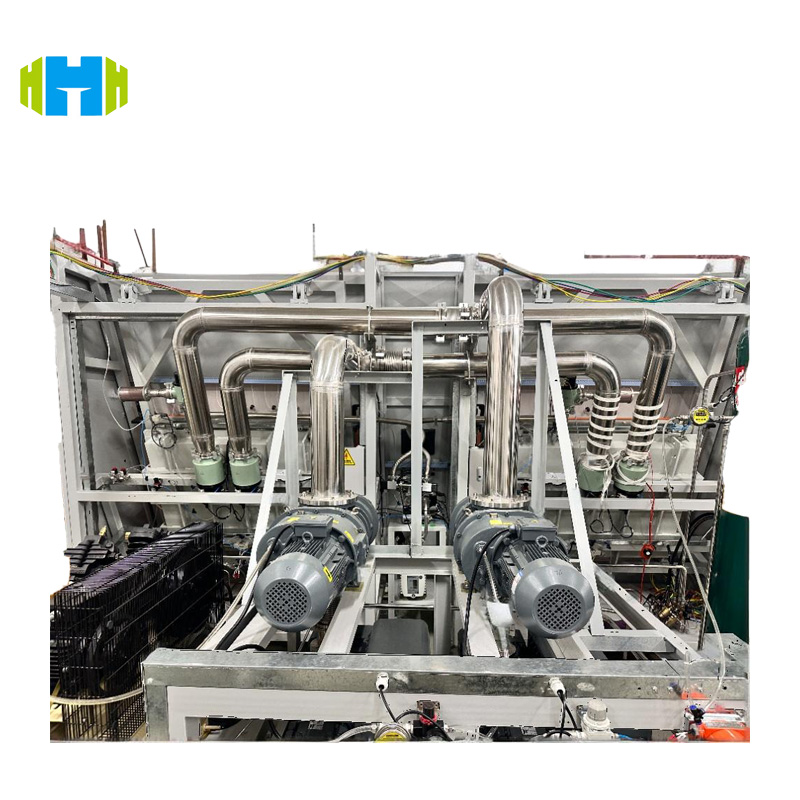

This equipment is customized for China National Electric Apparatus Research Institute by Guangzhou Hejin Automation Control Technology Co., Ltd. It is mainly used for dry leak detection of split - type air - conditioner evaporators and condensers, aiming to improve production quality and efficiency.

Item No. :

HJ-APAT-006Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

Technical Parameters:

|

Parameter |

Specification |

Value |

|

Power Supply |

Power Supply Voltage: 380V/50HZ, <82KW |

- |

|

Workpiece - related Parameters |

Workpiece Name: Split - type machine condensers and evaporators Workpiece Inner Volume: Less than 5L (High - pressure tank helium volume can simultaneously fill 20 workpieces) |

4L |

|

Vacuum Chamber Leak Detector Parameters |

Minimum detectable leak rate: 3.5*10 - 11Pa.m3/s Maximum inlet pressure: 300Pa Response time: less than 1 second |

3.5*10 - 11Pa.m3/s 250Pa 0.8s |

Application field:

Vacuum Chamber Parameters:Inner Dimensions: H850W1200D350 (with a 20mm - thick removable partition, and the height above and below the partition is 590mm) Number: 2 Inner Volume: 357L Door Opening and Closing Method: Lift - type door, outside - the - box method Workpiece Entry and Exit Method: Manual

Testing Parameters:Large Leak Test Pressure: 2.0 - 4.0MPa (with electric contact pressure gauge indication and filtration device for inlet pressure) Helium Filling Pressure: 0.90 - 1.3Mpa leak detection Accuracy: 1 gram/year Pre - evacuation Vacuum Degree: ≤1000Pa Recovery Vacuum Degree: ≤1000Pa Helium Recovery Rate: ≥98% Helium Control Concentration: ≥80% Accurate Detection Rate: ≥99.5%。Value:3.0MPa 1.1Mpa - 800Pa 900Pa 99% 85% 99.8%

Cycle Time:Check large leak (1 system, 1 channel): 20 seconds/channel (meets 20s/part) Evacuation and helium filling station (1 system, 1 channel): 18 seconds/part Vacuum chamber station: 90 seconds per single chamber (including 10 - second manual time), 45 seconds per chamber with two - chamber linkage, meets < 22.5 seconds/part Recovery station (1 system, 1 channel): 20 seconds/channel。Value:20s 18s 20s (per part in two - chamber operation) 20s

Main Components:Workpiece leak - detection, evacuation, and helium - filling system: workpiece evacuation pump SV25 (Leybold, 2 sets), valve bank assembly (Hejin, 2 sets), etc.

Vacuum chamber and leak detector part: leak detector (INFICON, 1 set), main extraction pump (Edwards vacuum pump unit, 2 sets), etc.

Recovery part: low - pressure tank (1 set), high - pressure tank (1 set), etc.

Electrical control part: PLC (Mitsubishi, 1 set), touch screen (Mitsubishi/Weinview, 1 set), etc.

Our equipment is designed and manufactured in strict compliance with the highest industry standards. We adhere to a meticulous quality control process, using high - quality materials and advanced manufacturing techniques to ensure the stability and reliability of the equipment. Every component is carefully selected and rigorously tested to meet or exceed performance expectations.

In conclusion, our Vacuum Chamber Helium Leak Detection Equipment for Evaporators and Condensers is a game - changer in the air - conditioner manufacturing industry. With its advanced technology, high - precision performance, efficient workflow, and exceptional after - sales service, it is the ideal choice for manufacturers looking to enhance product quality, improve production efficiency, and gain a competitive edge in the market. Invest in our equipment today and experience the difference it can make in your manufacturing process.

Hot Tags :