What Are You Looking For?

What Are You Looking For?

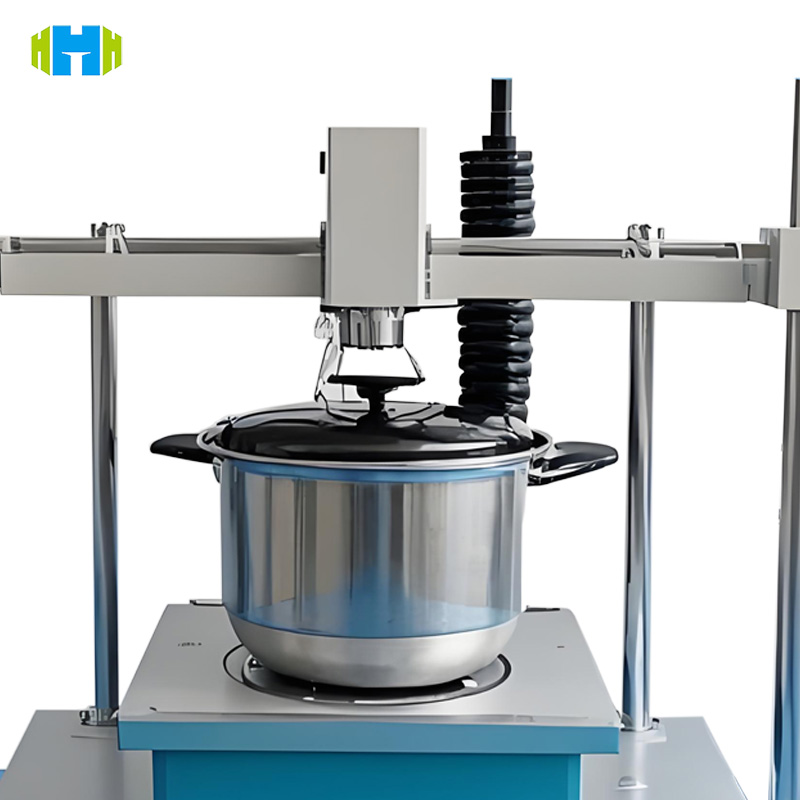

Guangzhou Hejin Automation Control Technology Co., Ltd. (Turkish Branch) specializes in the field of automation control technology. The wear resistance testing equipment for rice cooker inner pot coatings it produces is a professional device specifically designed to test the wear resistance of the inner pot coatings of rice cookers.

Item No. :

HJ-HAPT-002Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

Turkiye,ChinaSupply Ability :

1 set per 3 monthsLead Time :

90 Working DaysConventional packaging :

PlywoodRice cooker liner coating wear resistance test equipment

Product Introduction:

The equipment can simulate the friction and wear of the coating suffered by the rice cooker liner during daily use, and accurately measure and evaluate the wear resistance of the liner coating. Through scientific testing procedures and advanced technical means, it provides manufacturers with reliable liner coating quality inspection data to help improve product quality.

Product Features:

High-precision testing: Using advanced sensors and precise transmission systems, it can accurately control the friction force, speed and stroke during the test process to ensure the accuracy and reliability of the test data.

Simulate real scenarios: Fully consider the various situations of the rice cooker liner in actual use, such as the friction between the liner and the rice spoon when cooking, the friction during the cleaning process, etc., so that the test results are closer to actual applications.

Automated operation: With a highly automated control system, the operator only needs to set the test parameters, and the equipment can automatically complete the entire test process, greatly improving the test efficiency and reducing manual operation errors.

Versatility: It can be applied to the coating test of rice cooker liner of different materials and specifications to meet diverse production needs.

Technical standards:

ISO 15624:2015 "Test method for wear resistance of coatings of household and similar electrical appliances"

GB/T 4214.1-2017 "Test method for noise of household and similar electrical appliances Part 1: General requirements"

Technical parameters:

| Item | Parameters |

| Friction intensity | can be freely adjusted in the range of 1-50N, with a resolution of 0.1N |

| Friction speed | 10-100 times/minute, can be accurately set |

| Test stroke | 5-50mm, can be adjusted according to the size of the inner pot |

| Test stations | 1 set |

| Display mode | color touch screen |

| Voltage | 220V/60Hz |

| Power | 0.2W |

Application areas:

Rice cooker manufacturers: used for quality inspection of inner pot coating on the production line to ensure that the inner pot coating of each rice cooker shipped has good wear resistance and improve the overall quality of the product.

Third-party testing agencies: provide professional inner pot coating wear resistance testing services for various rice cooker brands, issue authoritative test reports, and provide a basis for market supervision and product quality evaluation.

Detailed pictures:

FAQ:

Q1: Is the equipment complicated to operate? Does it require professional training?

A: The equipment operation is relatively simple and has a highly automated control system. However, in order to ensure that users can master the operation methods and maintenance points of the equipment, we will provide users with professional training services, including equipment operation, daily maintenance, common troubleshooting and other aspects.

Q2: How long is the service life of the equipment?

A: Our equipment uses high-quality components and advanced manufacturing processes. Under normal use and maintenance, the service life can reach more than 10 years. At the same time, we also provide comprehensive after-sales service to ensure that problems encountered during the use of the equipment can be solved in time.

Q3: What should I do if the equipment fails during the test?

A: If the equipment fails during the test, our after-sales service team will respond within 24 hours after receiving user feedback, and provide remote technical support or arrange professional technicians to repair on site according to the specific situation.

After-sales service:

Installation and commissioning: After the equipment arrives, we will arrange professional technicians to go to the user's site for free installation and commissioning to ensure that the equipment can operate normally and reach the best working state.

Training service: Provide users with comprehensive training services, including equipment operation, daily maintenance, common troubleshooting, etc., to ensure that user operators can master the use of the equipment.

Warranty service: The equipment provides a free warranty period of 1 year from the date of acceptance. During the warranty period, if the failure is caused by the quality problem of the equipment itself, we will replace the parts and repair them free of charge.

Technical support: Provide 7×24 hours of technical consulting services. If users encounter any problems during use, they can contact our technical support team at any time, and we will provide solutions to users in a timely manner.

Accessories supply: Provide various original accessories required for the equipment for a long time to ensure that users can replace the parts of the equipment in time when they are damaged, so as to ensure the normal operation of the equipment.

Hot Tags :