What causes the outlet pressure to drop when the compressed air booster pump is started?

May 14, 2025

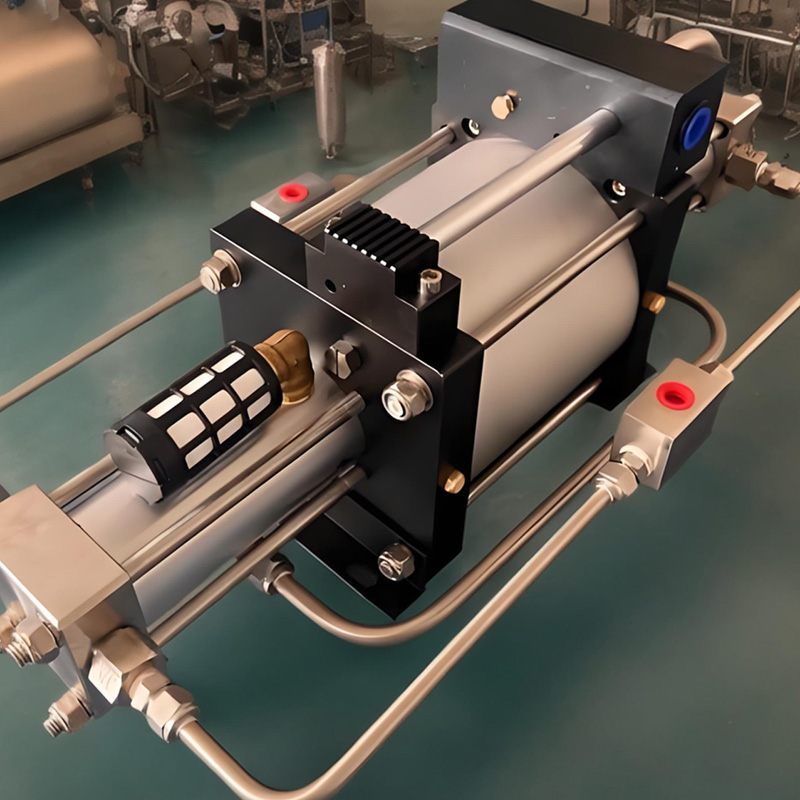

Compressed air booster pumps are widely used in the industrial field, but in actual use, many users report that the outlet pressure drops instead of rises after startup. This phenomenon seems contradictory, but it involves multiple factors such as aerodynamic principles, system design defects, and insufficient operation and maintenance management. This article will combine professional theory with actual cases to analyze the core reasons for the pressure drop and provide optimization solutions.

1. Core reason: imbalance between compressed air supply and demand

The air booster pump is essentially a pneumatic device, and its working power depends on the supply of external compressed air. When the booster pump starts, it will consume additional compressed air flow. If the air compressor's air supply capacity is insufficient, the total system pressure will inevitably drop.

Data case: Assuming that the displacement of an air compressor is 1 m³/min, the original equipment (such as dry gas seal) consumes 0.6 m³/min, and the system pressure can be maintained at 0.6 MPa. If the booster pump needs to consume an additional 0.5 m³/min after starting, the total demand reaches 1.1 m³/min, which exceeds the air compressor's supply capacity, and the pressure drops sharply from 0.6 MPa to a lower level.

Theoretical basis:

According to the Bernoulli equation, the law of conservation of fluid energy shows that when the flow demand exceeds the supply, the ratio of kinetic energy converted into pressure energy is unbalanced, resulting in a pressure drop. At the same time, the relationship between flow and pressure follows the formula:

Q = A × v

(where Q is flow, A is cross-sectional area, and v is flow velocity)

When the flow velocity increases, the pressure can decrease, further exacerbating the insufficient outlet pressure.

2. Analysis of common specific reasons

1.Improper selection or performance degradation of air compressor

Selection error: The superimposed flow requirements of the booster pump and the original equipment were not calculated, resulting in insufficient air compressor capacity.

Performance degradation: After long-term use of the air compressor, problems such as piston wear and filter element clogging will reduce the actual displacement. For example, due to improper maintenance of the air compressor by a user, the actual displacement dropped from the nominal 1 m³/min to 0.8 m³/min, which could not meet the requirements of the booster pump.

2. Leakage or component failure of the air system

Pipeline leakage: Loose joints or damaged pipes will cause compressed air to lose and pressure cannot be effectively maintained.

Check valve failure: If the check valve is not sealed tightly, the pressurized air will flow back to the low-pressure side, forming pressure fluctuations or even continuous leakage.

Filter clogging: Filter clogging will increase air path resistance, resulting in local pressure loss and reducing effective output.

3. Insufficient air tank capacity

The air tank is used to balance system pressure fluctuations. If the capacity is too small, it will not be able to buffer the instantaneous flow demand when the booster pump is started, and the pressure drop will be more significant. For example, in one case, after the user replaced the 5L gas tank with a 50L one, the pressure stability increased by 40%.

3. Solutions and optimization suggestions

1. Accurate selection and flow calculation

Flow calculation: Before selecting the booster pump, the total required flow must be calculated

(Qtotal = Qequipment + Qbooster pump), and the air compressor displacement must be at least 1.2 times the total demand.

Matching gas tank capacity: Recommended gas tank volume

V≥Qtotal×t/60, where t is the shortest working cycle of the booster pump (unit: second).

2. System maintenance and troubleshooting

Regular inspection: Check the pipeline sealing, filter status and check valve function every month, and replace aging parts in time.

Air compressor maintenance: Clean the filter element and replace the lubricating oil according to the manual to ensure stable displacement. For example, Atlas Copco's preventive maintenance contract can reduce energy efficiency losses by 30%.

3. Technology upgrade and redundant design

Dual pump parallel: For high reliability scenarios, a dual booster pump parallel design is adopted. When a single pump fails, the other pump automatically fills the position.

Intelligent monitoring: Install pressure sensors and IoT modules to monitor pressure fluctuations in real time and issue early warnings. For example, Atlas Copco’s “Intelligent Star” system can identify leakage risks in advance.