What Are You Looking For?

What Are You Looking For?

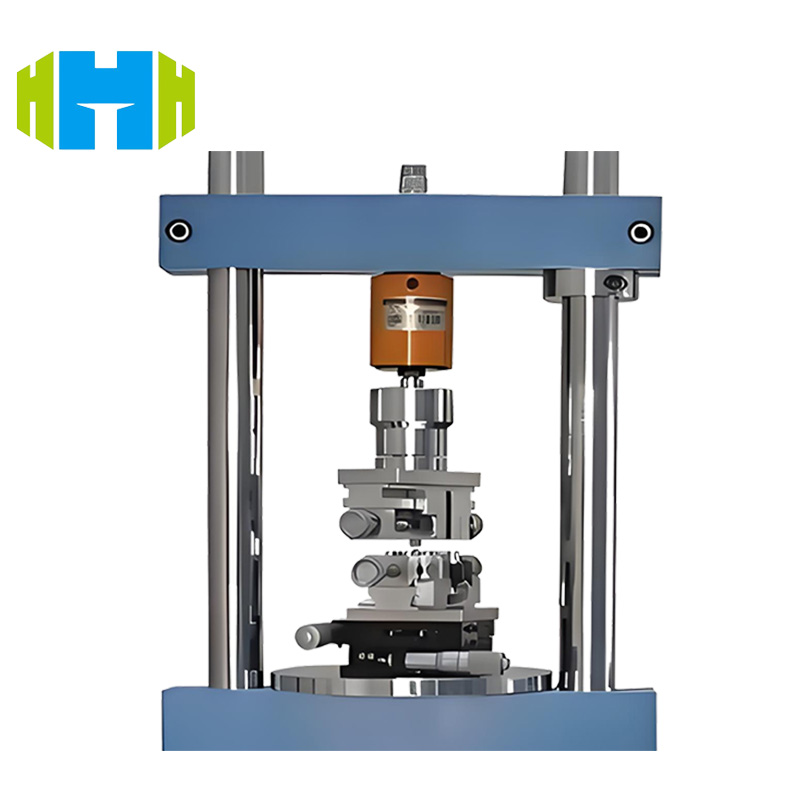

In the world of industrial electrical appliances, the reliability of connectors is of utmost importance. The Insertion and Extraction Force Testing Machine plays a crucial role in guaranteeing the quality and performance of these connectors. This article will provide a detailed introduction to this testing machine, highlighting its key features and parameters.

Item No. :

HJ-IEPTE-001Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

The Insertion and Extraction Force Testing Machine is specifically designed to measure the forces required to insert and extract electrical connectors. It simulates the real-world conditions under which connectors are used, ensuring that they can withstand repeated mating and unmating cycles without failure. By accurately assessing the insertion and extraction forces, manufacturers can identify potential issues with the connector design or manufacturing process, and take corrective actions to improve the reliability of their products.

Key Testing Parameters

|

Testing Parameter |

Description |

Importance |

|

Force Measurement Range |

Can measure forces from [min:1] to [max:5]. Useful for different connectors and applications with varying force needs. |

Allows testing diverse connectors and ensures machine suits manufacturing requirements. |

|

Number of Test Cycles |

Can be set for dozens to thousands of insertion/extraction cycles. Determines durability test. |

Assesses long-term reliability and identifies wear/fatigue issues. |

|

Connector Fixture Design |

Has a customizable fixture for various connectors. Ensures proper alignment and holding. |

Facilitates testing different connectors and ensures accurate results. |

Testing Process and Methodology

The testing process begins with carefully preparing the electrical connector sample. The sample is firmly mounted onto the connector fixture of the Insertion and Extraction Force Testing Machine. The desired force measurement range, test speed, and number of test cycles are set according to the specific requirements of the connector and the application. Once the parameters are configured, the machine initiates the insertion and extraction operations. During the test, the machine precisely measures and records the forces exerted at each stage of the mating and unmating process. High-precision sensors are used to capture the force data, which is then analyzed to determine if the connector meets the specified performance standards. After the completion of the test cycles, the connector is inspected for any signs of damage, such as bent pins, loosening of the housing, or wear on the contact surfaces. Based on the test results, manufacturers can make informed decisions about the acceptability of the connector design or take measures to improve its performance.

Benefits of Using the Insertion and Extraction Force Testing Machine

Enhanced Product Quality: By accurately measuring the insertion and extraction forces of connectors, manufacturers can ensure that their electrical appliances are equipped with reliable connectors. This reduces the risk of connection failures, which can lead to malfunctions or even safety hazards. High-quality connectors contribute to the overall performance and reliability of the product, enhancing customer satisfaction.

Improved Design Optimization: The test data obtained from the machine provides valuable insights for connector designers. They can use this information to optimize the design of the connector, adjusting factors such as the shape of the pins, the material of the housing, or the contact design to improve the insertion and extraction characteristics. This iterative design process based on test results leads to more efficient and reliable connector designs.

Cost Savings: Identifying and resolving potential connector issues early in the design or manufacturing process can prevent costly recalls, repairs, or replacements of electrical appliances. By ensuring the reliability of connectors from the start, manufacturers can avoid the financial losses associated with product failures and improve their bottom line.

Compliance with Standards: The use of the Insertion and Extraction Force Testing Machine helps manufacturers meet industry standards and regulations related to connector performance. This is essential for market access and maintaining a good reputation in the industry. It demonstrates the manufacturer's commitment to producing high-quality and safe electrical products.

In conclusion, the Insertion and Extraction Force Testing Machine is an indispensable tool for manufacturers of industrial electrical appliances. Its ability to accurately measure and evaluate the insertion and extraction forces of connectors, along with its advanced features and parameters, makes it a valuable investment for ensuring the reliability and quality of electrical products. By using this testing machine, manufacturers can enhance the performance of their products, gain a competitive edge in the market, and build customer trust.

Hot Tags :