What Are You Looking For?

What Are You Looking For?

The scratch resistance tester of Guangzhou Hejin Automation Control Technology Co., Ltd. (Turkey Branch) is an advanced equipment designed and developed for accurately evaluating the scratch resistance of material surfaces. It combines a precise mechanical structure with an intelligent control system to simulate the scratch effects suffered by the material surface under various actual working conditions, providing a reliable and efficient solution for material surface quality testing and performance research. Whether it is the exploration of new materials in scientific research laboratories or the control of product quality on industrial production lines, the scratch resistance tester can play an important role.

Item No. :

HJ0604AMinimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TürkiyeSupply Ability :

10 set per monthLead Time :

60 Working DaysConventional packaging :

PlywoodIndustrial special scratch resistance tester equipment

Product Introduction:

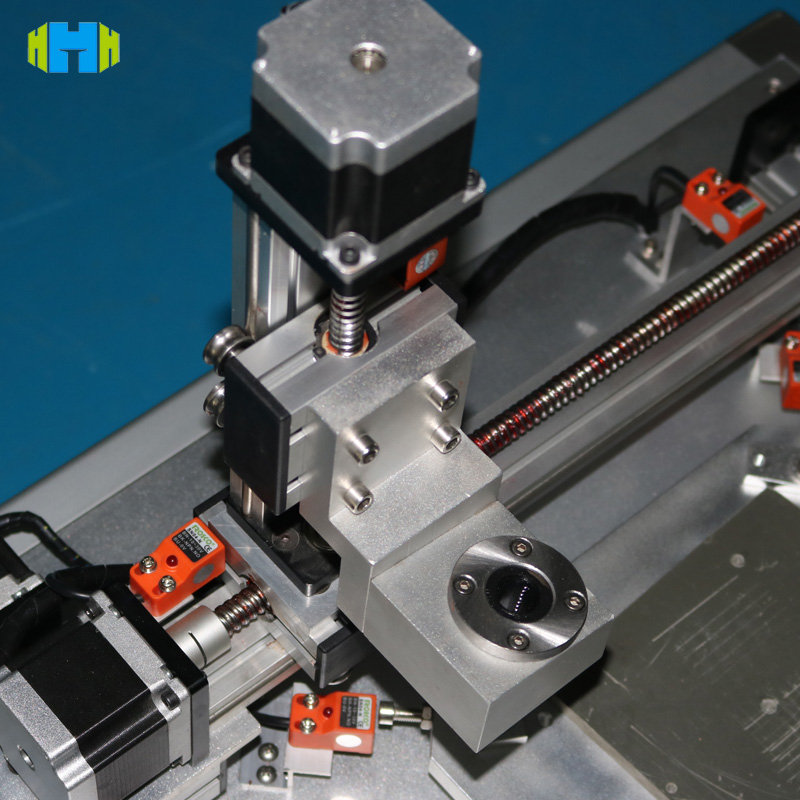

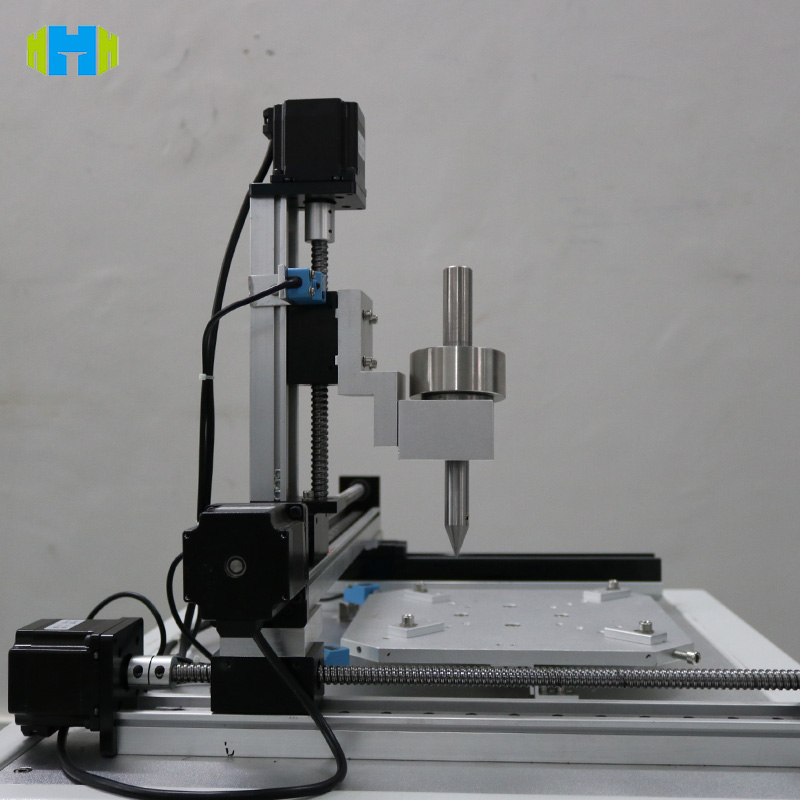

This scratch tester uses a high-precision drive device to make the scratch tool scratch the surface of the material under test at a precisely set speed and pressure. By accurately measuring various parameters during the scratching process, such as scratch depth, scratch width, scratch force, etc., it comprehensively evaluates the scratch resistance of the material. The equipment is equipped with advanced sensors and data acquisition systems, which can monitor and record the entire process data of the scratch test in real time to ensure the accuracy and reliability of the data. At the same time, the operation interface is simple and intuitive, which makes it easy for operators to set test parameters and control the equipment, greatly improving work efficiency.

Product Features:

1. High-precision measurement: The high-resolution sensor can accurately measure the tiny changes in the scratching process, providing a strong guarantee for the accurate evaluation of the scratch resistance of the material.

2. Multiple scratch modes: Supports multiple scratch modes such as linear scratch and circular scratch, which can be flexibly selected according to the requirements of different materials and test standards to meet diverse testing needs.

3. Intelligent control: The equipment has an intelligent control system that can automatically control parameters such as scratch speed and pressure, and can automatically stop according to preset conditions, effectively reducing human operation errors and improving the repeatability and stability of the test.

4. Sturdy and durable structure: The whole is made of high-quality metal materials, the structure is sturdy and stable, and can withstand long-term and high-intensity testing work to ensure the service life and reliability of the equipment.

5. Wide adaptability: It is suitable for various types of materials, including metals, plastics, ceramics, coatings, etc., and has a wide range of material testing compatibility.

Technical standards:

ISO 1518-2019 "Paints and varnishes - Scratch test"

ASTM D7027-18 "Standard test method for determination of scratch hardness of organic coatings by pendulum scratch hardness tester" etc.

Technical Parameters:

| Project | Parameters |

| Device Model | HJ0604A |

| Vertex Angle | 40° |

| Rounding radius | 0.25mm±0.02mm |

| Scratching speed | 20±5mm/s, presettable |

| Scratching pressure | 10N±0.5N, can be equipped with 20N weight to reach 30N±0.5N pressure; |

| Scratching spacing | 0-50mm, presettable |

| Scratching angle | 80-85°, fixed by fixture |

| Power supply | 220V/60Hz |

Test items:

1. Scratch force test: Accurately measure the force applied to the material surface during the scratching process to evaluate the material's ability to withstand the scratch force.

2. Scratch depth test: Real-time monitoring and recording of the scratch depth formed by the scratch tool on the material surface, reflecting the scratch resistance of the material surface.

3. Scratch width measurement: Obtain the scratch width data through specific imaging or measurement methods to further analyze the damage on the material surface.

4. Scratch morphology analysis: With the help of a microscope or imaging system, observe the microscopic morphology of the scratch surface, such as the flatness of the scratch edge, the accumulation or peeling of the material, etc., to provide a basis for material failure analysis.

Application areas:

Automotive industry: used to test the scratch resistance of automotive interior materials, body coatings, plastic parts, etc., to ensure the appearance quality and durability of the product during long-term use.

Electronic and electrical industry: Scratch resistance tests on electronic product housings, display screens, circuit board coatings, etc., to protect products from scratch damage during production, transportation and use.

Furniture manufacturing: Evaluate the scratch resistance of furniture surface coatings, decorative panels, etc., to improve the quality and market competitiveness of furniture products.

Coatings and coatings industry: In the process of coating research and development, scratch resistance tests are performed on new coating formulas to optimize the performance indicators of coatings and provide data support for coating quality control.

Scientific research institutions: Widely used in materials science research, such as the development and performance evaluation of new materials, to provide experimental data for the study of the relationship between the microstructure and macroscopic performance of materials.

Detail pictures:

After-sales service:

Warranty period: This scratch tester provides a 1-year warranty period. During the warranty period, we will provide free repair and replacement of parts for failures caused by equipment quality problems.

Technical support: We have a professional technical team that can provide users with 7×24 hours of technical consulting services. Whether it is equipment operation problems or test technical problems, users can contact us at any time, and we will answer you wholeheartedly.

Training service: Provide users with free equipment operation and maintenance training services. The training methods include on-site training and online training, which can be flexibly arranged according to user needs. Ensure that users can master the operation skills and maintenance points of the equipment.

Equipment upgrade: We will continue to pay attention to the development of industry technology and provide users with equipment software and hardware upgrade services to ensure that the equipment always maintains advanced performance and functions to meet users' changing testing needs.

After-sales response time: After receiving the user's after-sales request, we will respond within 72 hours. For simple problems, we will assist users to solve them through telephone or remote guidance; for problems that require on-site repair, we will arrange technicians to provide door-to-door service within 15 working days.

Hot Tags :