What Are You Looking For?

What Are You Looking For?

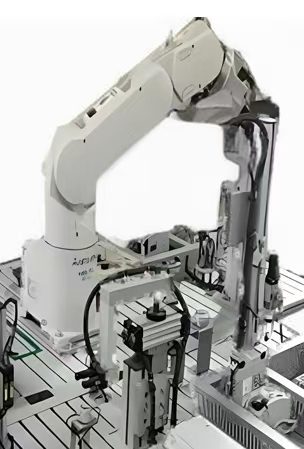

In the modern manufacturing landscape, industrial robots play a crucial role in enhancing productivity and efficiency. To ensure these robots operate at their peak performance, a comprehensive performance testing system is essential. This article delves into the details of the industrial robot performance testing system, highlighting its key features and parameters.

Item No. :

HJ-IEPTE-007Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

The industrial robot performance testing system is designed to evaluate various aspects of a robot's capabilities. It employs advanced sensors and measurement techniques to collect data during the robot's operation. This data is then analyzed to assess the robot's performance against predefined standards and specifications.

|

Testing Parameter |

Description |

Importance |

Simulated Values |

|

Motion Accuracy |

Measures the deviation between the robot's actual and commanded positions, covering positional accuracy, repeatability, and resolution. |

Ensures precise task execution and meets quality requirements. |

Positional accuracy: ±0.1mm, Repeatability: ±0.05mm, Resolution: 0.01mm |

|

Load Capacity |

Indicates the maximum weight the robot can handle without performance degradation. |

Defines the scope of tasks and affects manufacturing productivity. |

5 kg - 500 kg |

|

Repeatability |

Tests the robot's ability to return to the same position consistently. |

Ensures reliable operation and product uniformity in mass production. |

±0.08mm |

|

Speed and Acceleration |

Evaluates the robot's movement speed and velocity change rate, affecting production cycle time. |

Enables efficient production, but requires balance with accuracy and safety. |

Maximum speed: 2 m/s, Maximum acceleration: 5 m/s² |

|

Torque and Force Measurement |

Measures the forces and torques exerted by the robot's joints and end - effectors. |

Ensures safe interaction with the environment and optimizes control algorithms. |

Torque range: 10 N·m - 500 N·m, Force range: 5 N - 500 N |

|

Path Planning and Tracking |

Assesses the robot's ability to accurately follow predefined paths and respond to obstacles. |

Allows safe and efficient navigation in complex workspaces. |

Path tracking error: ≤0.2mm |

The testing process typically begins with the calibration of the testing equipment to ensure accurate measurements. The robot is then subjected to a series of predefined tasks and motions, while the testing system collects data on the parameters mentioned above. The collected data is analyzed using specialized software, which generates reports and graphical representations of the robot's performance. These reports help manufacturers and users identify areas for improvement and make informed decisions about the robot's suitability for specific applications.

Quality Assurance: By accurately assessing the robot's performance, manufacturers can ensure that the robots meet the required quality standards before being deployed in production lines. This reduces the risk of defective products and costly rework.

Improved Productivity: Identifying and rectifying performance issues early in the development or deployment stage allows for optimized operation of the robot. This leads to increased productivity and efficiency in manufacturing processes.

Enhanced Safety: Testing the robot's performance under various conditions helps in identifying potential safety hazards. This enables manufacturers to implement appropriate safety measures and safeguards, protecting both the operators and the equipment.

Cost Savings: Investing in a performance testing system can save costs in the long run by preventing premature failures and reducing maintenance requirements. It also helps in optimizing the robot's operation, resulting in lower energy consumption and higher equipment utilization.

In conclusion, the industrial robot performance testing system is an indispensable tool for manufacturers and users of industrial robots. It provides a comprehensive and accurate assessment of the robot's capabilities, enabling them to make informed decisions and ensure optimal performance in various manufacturing applications. By investing in such a testing system, companies can enhance the reliability and productivity of their robotic workforce, ultimately gaining a competitive edge in the market.

Hot Tags :