What Are You Looking For?

What Are You Looking For?

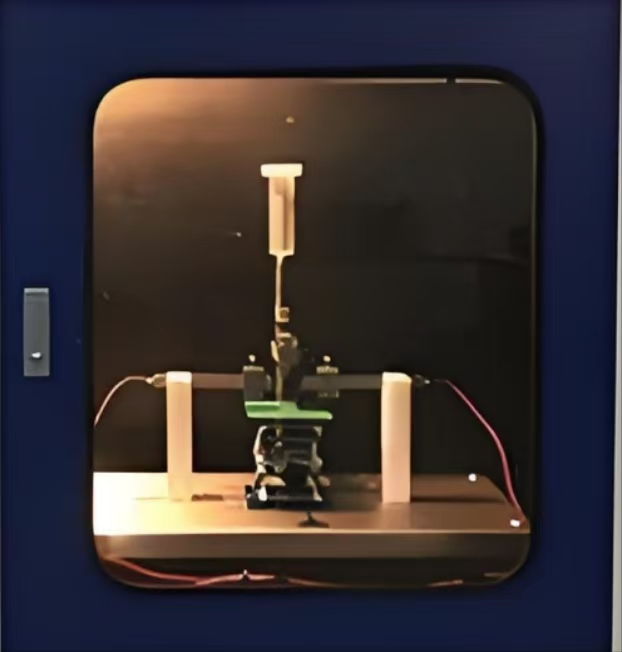

In the realm of electrical appliance manufacturing and quality control, the Leakage Tracking Tester stands as a critical instrument. It plays a vital role in evaluating the performance of insulating materials under the influence of electrical fields and electrolytes, ensuring the safety and reliability of electrical products.

Item No. :

HJ-IEPTE-006Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Days Plywood

Instrument Overview

The Leakage Tracking Tester is designed to mimic the conditions where an electrical appliance's insulation might be exposed to moisture, contaminants, or other factors that could lead to leakage currents and potential tracking failures. By subjecting test specimens to carefully controlled electrical stresses and environmental conditions, it provides valuable insights into the durability and resistance of insulating materials.

Key Parameter

|

Testing Parameter |

Description |

Importance |

Simulated Values |

|

Voltage Range |

The tester can apply a voltage that varies from the minimum to the maximum value. |

It helps comprehensively evaluate the performance of insulation materials across different voltages, ensuring safe operation in various electrical systems. |

Minimum: 100V, Maximum: 1000V |

|

Current Measurement Precision |

High - sensitivity current - measuring devices can precisely detect extremely low leakage currents. |

It enables early detection of incipient leakage issues and warns of insulation degradation in time for corrective actions. |

Minimum Detectable Current: 0.01mA |

|

Electrolyte Type and Concentration |

The tester can use different types of electrolytes and adjust their concentrations. |

It mimics the actual chemical environments of insulation, improving the relevance and reliability of test results. |

Electrolyte Types: Sodium Chloride Solution, Potassium Hydroxide Solution; Concentrations: 0.2mol/L, 0.5mol/L |

|

Test Duration and Cycling |

The test duration is adjustable, and cyclic tests can be carried out. |

It reflects the insulation performance over time and under variable conditions, similar to its actual service life. |

Test Duration: Shortest - 30 minutes, Longest - 48 hours; Cycle Times: 30 times |

The testing process begins with carefully preparing the test specimens of the insulating material. The specimens are then placed in the test chamber of the Leakage Tracking Tester. The appropriate electrolyte is introduced, and the voltage is set according to the desired test conditions. During the test, the tester continuously monitors the leakage current and records any changes in the specimen's appearance or electrical properties. If the leakage current exceeds a predefined threshold or if any visible tracking or degradation is observed, the test is halted, and the results are analyzed. Based on the test data, manufacturers can make informed decisions about the suitability of the insulation material for their products or take measures to improve its performance.

Enhanced Product Safety: By accurately assessing the leakage tracking resistance of insulating materials, manufacturers can ensure that their electrical products are less likely to experience insulation failures, reducing the risk of electrical shocks, fires, or other safety hazards. This is of utmost importance in protecting the end-users and maintaining the brand's reputation for safety.

Quality Assurance and Compliance: The tester enables manufacturers to meet industry standards and regulatory requirements related to insulation performance. It provides a reliable means of verifying that the products' insulation meets the necessary quality benchmarks, facilitating market access and avoiding potential legal issues.

Material Selection and Design Optimization: With the detailed data obtained from the tester, engineers can compare different insulation materials and select the most suitable ones for specific applications. It also helps in optimizing the design of electrical products by identifying potential weak points in the insulation system and suggesting improvements.

Cost Savings: Early detection of insulation problems through the use of the Leakage Tracking Tester can prevent costly product recalls, repairs, or replacements. By ensuring the reliability of the insulation from the design stage, manufacturers can avoid potential financial losses associated with insulation failures in the long run.

In conclusion, the Leakage Tracking Tester is an indispensable tool for the electrical industry. Its ability to precisely evaluate the leakage tracking characteristics of insulating materials under various conditions makes it an essential investment for manufacturers aiming to produce high-quality, safe, and reliable electrical products. With its advanced features and parameters, it empowers the industry to continuously improve the performance of electrical insulation and safeguard the integrity of electrical systems.

Hot Tags :