What Are You Looking For?

What Are You Looking For?

The constant temperature and humidity performance test chamber is used to test the impact of temperature and humidity on the performance, function and service life of the product. It provides equipment for environmental simulation tests under reproducible, certifiable and accelerated conditions. It is generally used for various temperature changes in the production, transportation, storage and use of product materials.

Item No. :

1 setMinimum Order Quantity (MOQ) :

HH0811Payment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TürkiyeSupply Ability :

10 sets per monthLead Time :

45 Working DaysConventional packaging :

PlywoodIndustrial grade constant temperature and humidity performance test chamber

Product Introduction:

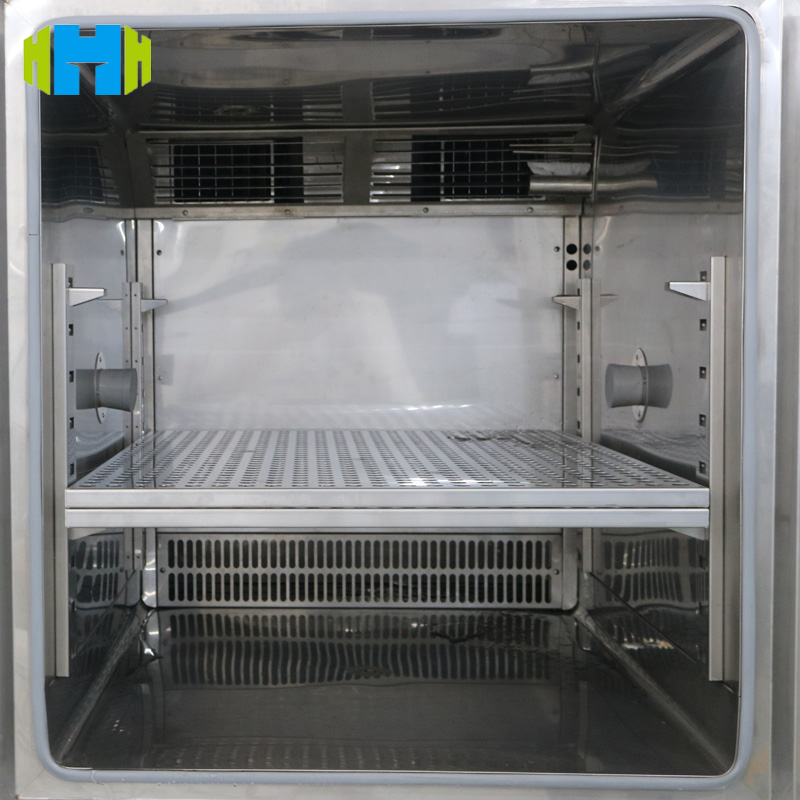

This test chamber adopts an integrated design concept. The outer shell is made of high-quality cold-rolled steel plate, and the surface is electrostatically sprayed. It not only has good corrosion resistance, but also effectively prevents the external environment from interfering with the internal equipment. The internal studio is made of stainless steel, which is smooth and easy to clean, and will not cause pollution to the test samples. The equipment is equipped with an advanced temperature and humidity control system, which can achieve high-precision temperature and humidity control and stable environmental simulation.

Product Features:

1. High-precision control: Using advanced PID control algorithm, the temperature control accuracy can reach ±0.5℃, and the humidity control accuracy can reach ±3% RH, ensuring the stability and accuracy of the test environment.

2. Wide range of temperature and humidity adjustment: The temperature range can be set arbitrarily between -70℃ and 150℃, and the humidity range can be adjusted between 20% RH and 98% RH to meet the testing needs of different products.

3. Rapid temperature rise and fall/humidity: With efficient cooling and heating systems, as well as advanced humidification and dehumidification devices, it can achieve rapid temperature rise and fall/humidity changes and shorten the test cycle.

4. Safe and reliable: Equipped with multiple safety protection devices, such as leakage protection, over-temperature protection, water shortage protection, etc., to ensure the safety of operators and equipment.

5. Humanized design: The operation interface is simple and intuitive, easy to operate and set. The equipment also has data recording and printing functions, which is convenient for users to manage and analyze test data.

Reference standards:

IEC 60068-2-1: specifies the low-temperature test method in the basic environmental test procedures for electrical and electronic products, which is used to assess the performance and reliability of products in low-temperature environments.

IEC 60068-2-2: is the high-temperature test method standard in the basic environmental test procedures for electrical and electronic products, which can determine the adaptability of products to storage and use under high-temperature conditions.

Technical Parameters:

| Project | Parameters |

| Temperature range | -70℃ to 150℃ |

| Humidity range | 20% RH to 98% RH |

| Temperature fluctuation | ±0.5℃ |

| Humidity fluctuation | ±3%RH |

| Heating rate | 1℃/min to 3℃/min (settable) |

| Cooling rate | 0.7℃/min to 1℃/min (settable) |

| Box dimensions | Various specifications are available, such as 500×600×700mm, 800×800×1000mm, etc. |

| Power requirements | AC 380V, 50Hz |

Test items:

Temperature adaptability test: Test the performance and reliability of the product under different temperature environments.

Humidity adaptability test: Evaluate the moisture-proof and mildew-proof properties of the product under different humidity conditions.

Temperature and humidity cycle test: Simulate the temperature and humidity changes that the product may encounter during actual use, and test the durability and stability of the product.

High temperature and high humidity test: Assess the product's tolerance in high temperature and high humidity environments.

Low temperature and low humidity test: Test the product's performance in low temperature and low humidity environments.

Test objects:

Electronic and electrical products: such as mobile phones, computers, home appliances, etc., to test their electrical performance and stability under different temperature and humidity environments.

Automotive parts: such as engines, sensors, electronic control systems, etc., to ensure their reliability under harsh environmental conditions.

Aerospace products: such as aircraft parts, avionics equipment, etc., to meet their strict environmental testing requirements.

Materials and components: such as plastics, rubber, metal materials, etc., to evaluate their physical and chemical properties under different temperature and humidity environments.

Detailed pictures:

FAQ:

Q1. : How long is the service life of the equipment?

A: Under normal use and maintenance, the service life of the equipment can reach more than 10 years.

Q2. : When the equipment fails, how long will it take to get a repair response?

A: We provide a 24-hour after-sales service hotline. After receiving the fault report, we will respond within 2 hours and arrange maintenance personnel to arrive at the site as soon as possible for repair according to the specific situation.

Q3. : Can the equipment be customized?

A: Yes. We can customize the size, temperature and humidity range, control accuracy, etc. of the equipment according to the specific needs of customers.

Q4. : How to arrange the transportation and installation of the equipment?

A: We are responsible for the transportation, installation and commissioning of the equipment. Before the equipment is shipped, we will conduct a comprehensive inspection and test of the equipment to ensure that the equipment is not damaged during transportation. After the equipment arrives at the customer's site, our professional technicians will install and debug it in time to ensure that the equipment can operate normally.

Hot Tags :