What Are You Looking For?

What Are You Looking For?

In the realm of industrial electrical equipment manufacturing and quality control, understanding the density of materials is of great significance. The Density Meter emerges as a crucial instrument for precisely measuring this essential property.

Item No. :

HJ-IEPTE-026Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

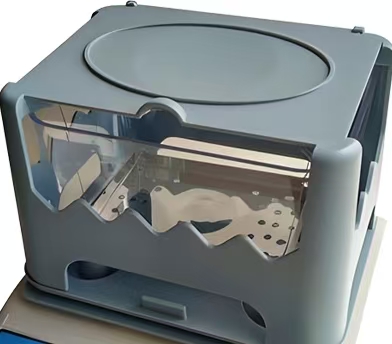

Overview of the Density Meter

The Density Meter is designed to determine the density of various liquids and solids used in industrial electrical applications. By accurately measuring density, manufacturers can ensure the quality and performance of materials, which in turn impacts the reliability of the final electrical products.

Key Testing Parameters

|

Testing Parameter |

Description |

Importance |

|

Measurement Range |

The Density Meter typically has a wide measurement range for both liquids and solids. For liquids, it can cover densities from [lower liquid density limit] to [upper liquid density limit], such as 0.5 g/cm³ to 2.0 g/cm³. For solids, the range might be from [lower solid density limit] to [upper solid density limit], like 1.0 g/cm³ to 10.0 g/cm³. This broad range allows it to handle different materials commonly encountered in the industry. |

Enables the measurement of a diverse array of materials, ensuring its versatility in industrial electrical applications. |

|

Accuracy |

It offers high accuracy, usually within a tolerance of ±[X] g/cm³. High precision is crucial as even a slight deviation in density can indicate potential material variations or impurities that could affect the electrical properties of the equipment. For example, in the production of insulating materials, precise density control is essential for maintaining proper electrical insulation performance. |

Guarantees reliable density measurements, providing a solid basis for quality assessment and material selection. |

|

Measurement Method |

Different Density Meters may use various measurement methods, such as buoyancy method, oscillation method, or radiation method. Each method has its advantages and is suitable for different types of materials. For instance, the buoyancy method is commonly used for liquids, while the oscillation method might be more appropriate for solid samples with irregular shapes. The choice of method depends on the nature of the material being tested. |

Allows for the selection of the most suitable measurement technique based on the specific material, enhancing the accuracy and effectiveness of the measurement. |

|

Sample Size Requirement |

The instrument has specific requirements regarding the sample size. For liquids, it may need a certain volume, say 10 ml to 100 ml depending on the model. For solids, the size and shape of the sample can also vary. This ensures that the measurement is representative of the material's density and that the instrument can operate effectively. |

Ensures proper sample preparation and measurement conditions for accurate density determination. |

|

Temperature Compensation |

Many Density Meters are equipped with temperature compensation features. Since density can be affected by temperature changes, especially for liquids, this function adjusts the measured density to a standard reference temperature. This is crucial for obtaining accurate and comparable density values across different measurement conditions. |

Accounts for the influence of temperature on density, providing more accurate and consistent results. |

Quality Control: By precisely measuring the density of materials, manufacturers can identify any deviations from the required standards. This helps in rejecting substandard materials and ensuring that only high-quality components are used in the production of industrial electrical equipment, thereby enhancing the overall product quality.

Material Selection: Understanding the density of different materials allows engineers to make informed decisions when selecting materials for specific electrical applications. They can choose materials with the most suitable density characteristics to optimize the performance of the equipment.

Process Optimization: Monitoring the density of materials during the manufacturing process can provide insights into process variations. By adjusting the process parameters based on density measurements, manufacturers can optimize the production process and improve efficiency.

Compliance with Standards: In many industries, there are strict regulations regarding the density of materials used in electrical products. Using a Density Meter enables manufacturers to comply with these standards and avoid potential legal issues.

In conclusion, the Density Meter is an indispensable tool for the industrial electrical equipment manufacturing industry. Its advanced features and parameters make it a valuable investment for ensuring the quality, reliability, and compliance of the production process.

Hot Tags :