What Are You Looking For?

What Are You Looking For?

The plate heat exchanger helium leak detection system of Guangzhou Hejin Automation Control Technology Co., Ltd. (Turkey Branch) is a professional equipment designed and developed for the air tightness detection of plate heat exchangers. It integrates advanced helium leak detection technology and automatic control means, and can accurately locate the leakage point of the plate heat exchanger while ensuring efficient detection, providing a reliable solution for the quality assurance of plate heat exchangers.

Item No. :

HJ027-1Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TürkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

PlywoodHelium leak detection system for plate heat exchangers

Product Introduction:

Plate heat exchangers are widely used in many industrial fields, and their air tightness directly affects the performance and operational safety of the equipment. This helium leak detection system detects helium leaks by filling the plate heat exchanger with helium and using the high-sensitivity detection characteristics of the helium mass spectrometer leak detector. The system has a high degree of automation, and can automatically complete the entire process from product loading, test preparation, test process to unloading, greatly improving the detection efficiency and accuracy, and effectively reducing labor costs and misjudgment rates.

Product Features:

High-precision detection: The use of advanced helium mass spectrometer leak detection technology ensures the high accuracy of the test results.

Fully automatic operation: The equipment is equipped with automatic calibration and diagnostic functions, which simplifies the operation process and reduces human errors.

Efficient and fast: The optimized design enables the equipment to complete the entire process from vacuuming to helium replacement to leak detection in a short time, greatly improving production efficiency.

Safe and reliable: The equipment is equipped with multiple safety protection measures, including pressure monitoring, temperature control and emergency stop buttons, to ensure the safety of operators.

Easy to maintain: The modular design makes the maintenance of the equipment simpler and more convenient. Key components are easy to disassemble and replace, reducing maintenance costs.

Strong adaptability: Suitable for plate heat exchangers of different specifications and models, whether small household or large industrial heat exchangers can be easily handled. In addition, it can adapt to different production environments and working conditions.

Data recording and traceability: The built-in data recording system can record the results of each test in detail, including leakage rate, test time and other information, which is convenient for subsequent quality tracking and problem analysis.

Environmental protection and energy saving: The use of oil-free vacuum pump technology and recycled helium reduces environmental pollution and resource waste, which is in line with the concept of green manufacturing.

Technical standards:

Follow international standards: ISO 20483:2017 "Plate Heat Exchanger Performance Test Method" to ensure that the test method is in line with international standards.

Comply with relevant industry standards: relevant industry standards

Technical parameters:

| Project | Parameters |

| Leak detection accuracy | 1x10-10 Pa·m'/s ~ 1 x10-7 Pa·m'/s |

| Minimum detectable leak rate | 5x10-10Pa·m'/s |

| Pressure range | 100 Pa-10 MPa |

| Detection cycle | 30 seconds - 300 seconds / piece (specific workpiece size) |

| Helium flow range | 10sccm - 1000sccm |

| Size | according to the design size of the workpiece |

| Weight | according to the weight of the customized size |

| Power supply | 220V~380V/50Hz/60Hz |

Application areas:

Refrigeration industry: In the production process of plate heat exchangers in refrigeration equipment such as air conditioners and refrigerators, ensure that the heat exchanger is leak-free and ensure the efficient and stable operation of the refrigeration system.

Chemical industry: Used for plate heat exchanger detection in chemical process flow to prevent medium leakage from causing safety accidents and production interruptions.

Power industry: In the heat exchange system of the power plant, the plate heat exchanger is tested for air tightness to ensure the normal heat exchange and improve energy utilization efficiency.

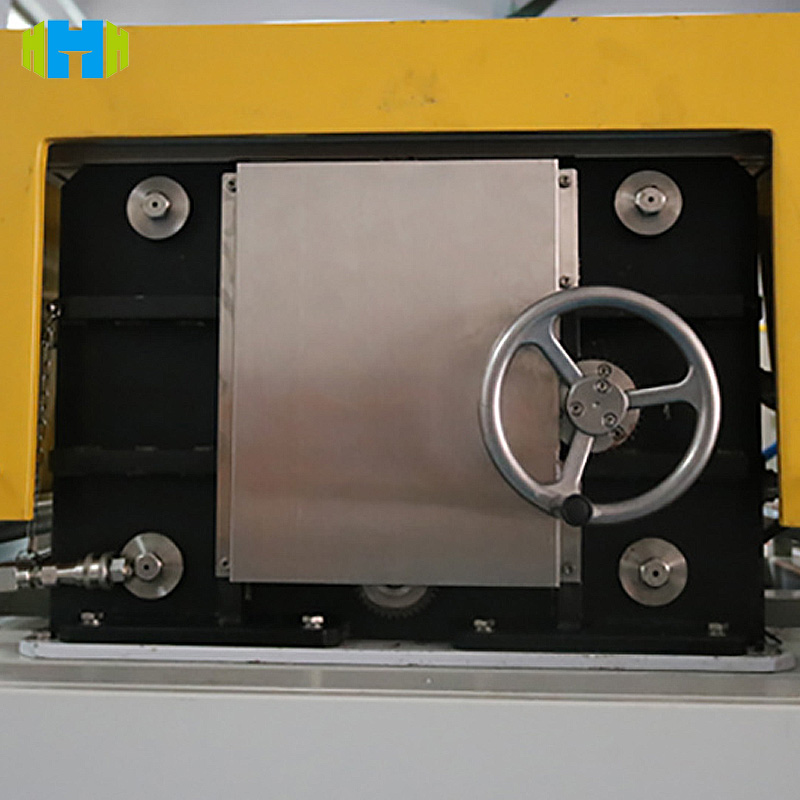

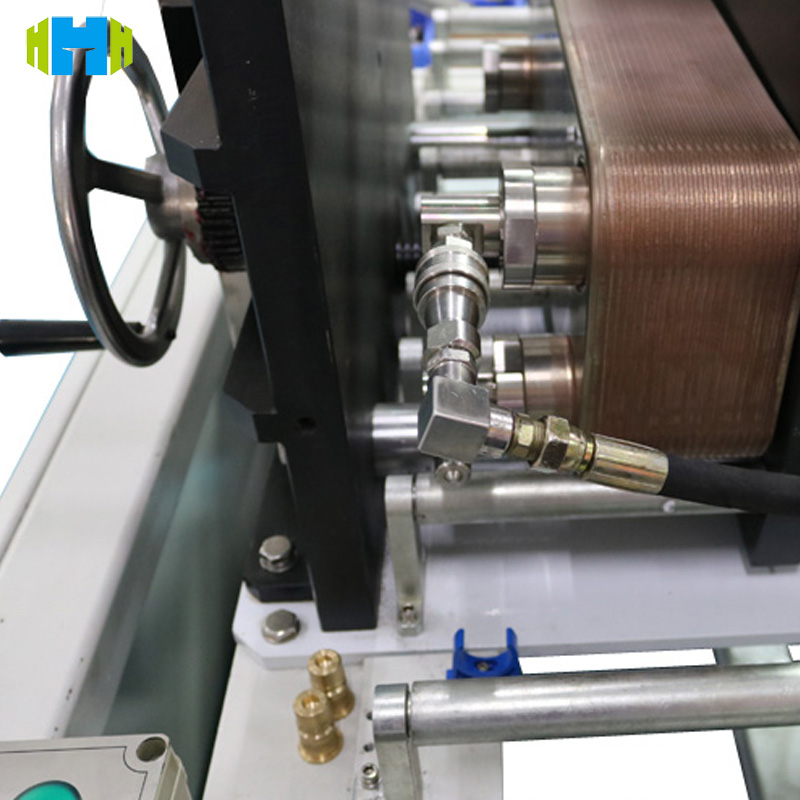

Detailed picture:

After-sales service:

1. Installation and commissioning

Professional technicians provide on-site installation and commissioning services to ensure that the equipment can operate normally at the customer's site, and provide on-site training for customer operators to familiarize them with the equipment's operating procedures and basic maintenance knowledge.

2. Warranty service

The equipment provides a 1-year warranty period from the date of acceptance. During the warranty period, the company will provide free maintenance services for equipment failures caused by non-human factors, including replacement of faulty parts, dispatching technicians for on-site repairs, etc.

3. Lifetime maintenance

After the warranty period, the company still provides lifetime maintenance services. Customers can sign a maintenance agreement with the company. The company will regularly visit customers, inspect and maintain the equipment, provide preferential maintenance services and original parts supply, and ensure the long-term and stable operation of the equipment.

4. Technical support

A 24-hour technical support hotline is set up. If customers encounter any problems during the use of the equipment, they can call the hotline at any time. The technicians will provide remote technical guidance or on-site solutions in a timely manner to ensure that the customer's production is not affected.

Hot Tags :