What Are You Looking For?

What Are You Looking For?

HH-RR-503S is designed for laboratory-level gas water heater performance testing. It supports full performance verification of water heaters in the power range of 0-40kW, and integrates 30+ core indicator tests such as thermal efficiency (accuracy ±0.8%), hot water output rate (resolution 0.1L/min), and safety protection (flameout response ≤30s). It uses imported high-precision sensors and intelligent measurement and control systems, complies with GB 6932 and EN 61326 international standards, and automatically generates full-item test reports. It is a professional testing platform for water heater manufacturers, scientific research institutions and third-party laboratories.

Item No. :

HH-NL-501Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C, T/TPrice :

NegotiatableProduct Origin :

CHINASupply Ability :

10 Set per monthLead Time :

90 DaysConventional packaging :

PlywoodIEC 60335 Laboratory-Level Precision Gas Water Heater Test System

Product Introduction

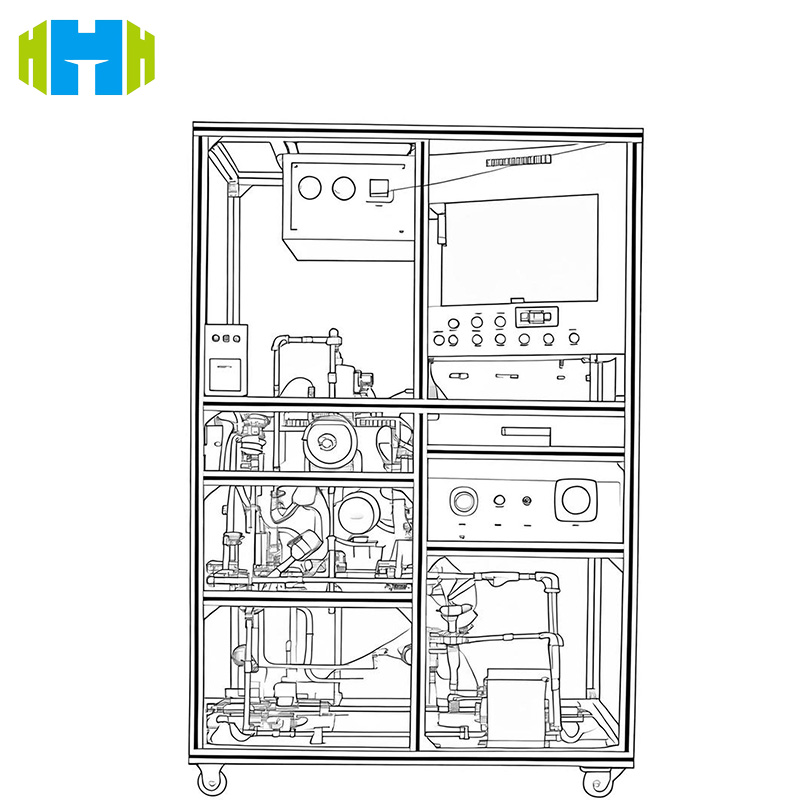

HH-RR-503S focuses on laboratory-level precision detection and realizes in-depth analysis of gas water heater performance through four core modules:

▎Full-power segment in-depth detection

Power and gas source adaptation:

0-40kW covers household (8-30kW) and commercial (30-40kW) water heaters, supports natural gas (12T/10T), liquefied gas (20Y) full gas source, gas pressure adjustment 500-3500Pa (resolution 10Pa), adapted to global gas source environment.

Water quality simulation capability:

Hardness 0-1000ppm, chloride ion 0-200ppm adjustable, with flow rate 0-30L/min control, verify the anti-scaling and corrosion resistance of the heat exchanger, and meet the GB/T 18870 water quality compatibility test requirements.

▎Multi-dimensional performance analysis

Thermal engineering and energy efficiency:

Thermal efficiency is tested by double platinum resistance method (±0.8% accuracy), supporting in-depth verification of first-level energy efficiency (≥90%);

Load adjustment ratio ≥5:1, hot water output rate resolution 0.1L/min, adapted to strict energy efficiency standards such as Energy Star;

Real-time analysis of flue gas composition (CO/NOx resolution 1ppm), supporting environmental certification testing.

Safety and reliability:

Air tightness detection accuracy reaches 0.005L/min (1.5 times pressure for 30min), flameout protection response ≤30s;

Electrical safety test: insulation resistance ≥10MΩ, withstand voltage 1800Vdc/1min, in line with IEC 60335 anti-electric shock requirements;

1000 start-stop cycles, 1000ppm hardness water quality long-term operation, simulating durability in actual use.

▎Intelligent measurement and control and data management

Operation and process:

The 15-inch touch screen has built-in 10+ standard templates (CCC/CE/Energy Star), supports custom processes, and reduces parameter setting time by 60%;

Switch between Chinese and English interfaces, adapting to multi-language laboratory environments.

Data traceability:

256GB solid-state storage collects 80+ parameters in real time and generates PDF reports with digital signatures (including UN/CE data formats);

Supports blockchain evidence storage and remote auditing, meeting ISO 9001 data traceability requirements.

▎High-precision sensor matrix

Core hardware:

German imported gas mass flow meter (±0.5% FS), electromagnetic water flow meter (±0.3% FS), platinum resistance temperature sensor (±0.2℃), through CNAS/CMA dual calibration, the accuracy is 1.5 times better than the national standard;

Dynamic pressure sensor (response time <5ms) captures water hammer impact and simulates extreme working pressure fluctuations (±20%).

Modular design:

Quickly switch the gas source module (natural gas → liquefied gas) in 30 minutes to reduce laboratory debugging costs;

The detachable water channel module supports high temperature (95℃) and high pressure (1.2MPa) expansion, suitable for special scene testing.

Product Features

Laboratory-grade accuracy: ±0.8% thermal efficiency, ±0.3% FS flow detection accuracy, adapted to the stringent requirements of international certifications such as UL/CE.

Full standard compatibility: built-in 15 international standard test procedures such as GB/EN/ASME, automatically generates multi-language reports (Chinese/English/Spanish/Arabic).

Extreme working condition simulation: -10℃ low temperature start-up, 3000m altitude combustion test, 1000ppm water hardness long-term operation, covering global usage scenarios.

AI data analysis: machine learning algorithm identifies 12 potential problems such as unstable combustion and sensor drift, and the accuracy of abnormal data warning is >99%.

Modular design: detachable gas/water module, complete gas source switching (natural gas → liquefied gas) within 30 minutes, reducing laboratory debugging costs.

International Reference Standards

GB 6932-2015 "Household Gas Instantaneous Water Heaters" (Clause 5 Thermal Efficiency; Clause 6 Safety Devices).

EN 61326-1:2013 "Electromagnetic Compatibility of Measuring Equipment" (Section 4 Radio Frequency Interference Limits).

Energy Star Program "Energy Efficiency Standard for Water Heaters" (Section 5 Thermal Efficiency ≥ 90%; Section 6 Standby Power Consumption ≤ 1W).

IEC 60335-2-34:2018 "Safety Requirements for Water Heaters" (Clause 11 Temperature Rise Test; Clause 15 Moisture Resistance).

ANSI Z21.10.3-2019 "Safety Standard for Gas Water Heaters" (Clause 8 Combustion Performance; Clause 12 Automatic Safety Devices).

ISO 9001:2015 "Quality Management System" (Clause 7.1.5 Calibration of Monitoring Equipment).

ASTM D6476-19 "Durability test method for gas water heaters" (Section 6 Cycle life test).

Technical Parameters

| Category | Parameter Details |

| Model | HH-RR-503S |

| Test Power Range | 0-40kW (Natural Gas/LPG/Manufactured Gas) |

| Gas Flow Measurement | ±0.5%FS Accuracy (Mass Flow Meter, Range: 0-6m³/h) |

| Water Flow Measurement | ±0.3%FS Accuracy (Electromagnetic Flow Meter, Range: 0-30L/min) |

| Temperature Range | Inlet: 5-30℃; Outlet: 10-90℃ (±0.2℃ Accuracy) |

| Pressure Regulation | Water Pressure: 0.05-1.2MPa (Resolution: 0.001MPa); Gas Pressure: 500-3500Pa |

| Thermal Efficiency | Test Accuracy ±0.8%, Supports 1st-Class Energy Efficiency (≥90%) Verification |

| Data Sampling Rate | 500Hz (Real-Time Acquisition of 80+ Parameters: Voltage, Current, Flow, etc.) |

| Leakage Detection | Liquid: ≤0.005L/min; Gas: ≤0.01m³/h (Mass Spectrometer Leak Detector) |

| Control System | PLC + Industrial PC, Support LabVIEW/Matlab Data Interface, Compatible with LIMS |

| Test Port Size | DN15-DN50 (NPT/RF Interfaces, Compatible with Rheem, A.O. Smith Models) |

| Power Supply | AC220V±10%/50Hz, Rated Power: 40kVA (Dual-Voltage Support: 220V/110V) |

| Protection Class | IP54 (Control Cabinet), IP67 (Test Chamber, Splash-Proof Design) |

| Dimensions | 4500×3000×2500mm (Including Water Tank, Gas Cabinet & Exhaust Treatment System) |

| Weight | 3000kg (All-Steel Frame + Anti-Corrosion Coating) |

| Communication | RS485/Modbus TCP/USB 3.0, Support OPC UA Protocol for Cloud Data Synchronization |

| Noise Level | ≤65dB (Measured at 1m Distance, No-Load Operation) |

Test objects and test items

Core test objects:

Household gas instantaneous water heaters (8-30kW, including condensing/instantaneous).

Commercial gas water heaters (30-40kW, volumetric/modular).

Special scenario water heaters (marine/plateau type, high-voltage module required).

Core test items:

Basic performance: rated heat load, hot water output rate, thermal efficiency, load adjustment range.

Energy efficiency and environmental protection: standby power consumption, CO/NOx emission concentration, energy efficiency level (GB 30720/Energy Star).

Safety performance: air tightness, flameout protection response time, overheating protection temperature, electrical insulation resistance.

Reliability: 1000 start-stop cycle test, water scaling simulation (1000ppm hardness operation for 1000 hours), vibration durability (10-50Hz).

Extreme working conditions: low air pressure start (85% Rated air pressure), high altitude combustion test (0-3000m), -10℃ low temperature start.

Control performance: water temperature control accuracy (±1℃), power adjustment response time (<10s), intelligent antifreeze function verification.

Hot Tags :