What Are You Looking For?

What Are You Looking For?

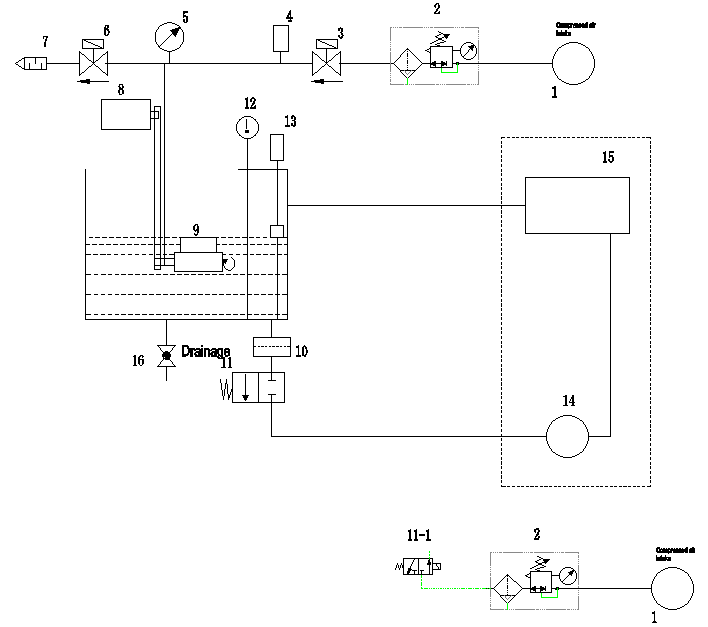

The Fabrication Integrity and Initial Bubble Point Testing Apparatus for Filter Media is employed to ascertain the structural integrity of a filter element (by confirming the absence of bubbles) or to pinpoint the location of the largest pore in the filter element by identifying the initial bubble point.

Fabrication Integrity and First Bubble Point Test Auto parts air tightness testing equipment

Product Summary:

Assessment of fabrication integrity determines whether the filter element is suitable for further use or testing. The initial bubble point is determined by continuing the fabrication integrity test. It is important to note that the initial bubble point is not a functional attribute of the filter element; specifically, it cannot be used to predict filtration rating, efficiency, or retention capacity. Instead, it serves solely as informational.

Testing Mechanism:

The filter element under examination is manually installed in a designated clean test vessel filled with test liquid. The filter element is immersed in the test liquid and rotates automatically during the test. The air pressure is incrementally increased automatically throughout the test. The operator manually documents the corresponding pressure value and the location of the bubble point, which are then entered into a computer to automatically produce a test report.

Standard:

The fabrication integrity and first bubble point test rig for filter element meet the standard of ISO 2942-2004, GB/T 14041.1-2007.(Auto parts air tightness testing equipment)

Test object:

Filter element used in hydraulic fluid power systems.

Parameters:

|

Air compressor |

With filter and pressure regulator, adjustable up to 200 mbar |

|

Gas pressure sensor |

With an accuracy of ± 5% of the reading |

|

Liquid temperature sensor |

With an accuracy of ± 5 °C |

After-sales service:

In terms of after-sales service, we provide comprehensive services. A one-year quality assurance period is provided from the final acceptance. During this period, the supplier provides free technical support. If the equipment fails, the supplier will respond within 24 hours and provide a solution within 48 hours. If spare parts are required, the supplier will assist in procurement and installation, and try to solve the problem within 72 hours. Even after the warranty period, the supplier can still provide timely, high-quality, cost-effective technical services and spare parts to ensure the long-term and stable operation of the equipment.

Hot Tags :