What Are You Looking For?

What Are You Looking For?

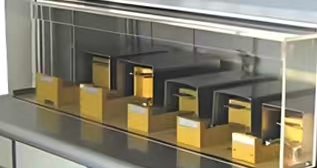

A contactors testing bench is a specialized equipment used in the field of electrical engineering to evaluate and analyze the performance of contactors. This article provides a detailed introduction to contactors testing benches, including their functions, testing parameters, and the significance of these parameters in ensuring the reliable operation of contactors.

Item No. :

HJ-IEPTE-008Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

Contactors are widely used in electrical control systems to switch electrical circuits on and off. They play a crucial role in various industrial applications, such as motor control, lighting control, and power distribution. To ensure their proper functioning and reliability, it is essential to conduct regular tests using a contactors testing bench.

Key Parameters

|

Parameter Category |

Parameter Name |

Simulated Value (Example) |

Parameter Significance |

|

Coil Parameters |

Coil Resistance |

80Ω (for a 10A, 220V AC contactor) |

Affects the current through the coil and the generated magnetic force. Deviations may indicate coil short circuits or open circuits. |

|

Coil Parameters |

Coil Inductance |

100mH (for a contactor used in general industrial control circuits) |

Determines the inductive reactance, influencing the time for the magnetic field to build up and collapse, which is crucial for the contactor's dynamic behavior and response to control signals. |

|

Contact Parameters |

Contact Resistance |

80mΩ (for a contactor with high - performance requirements) |

Measures the resistance between contact surfaces when closed. Low resistance minimizes power losses and heating; high resistance can cause voltage drops, reduced efficiency, and premature failure. |

|

Contact Parameters |

Contact Bounce Time |

6ms (for a contactor with advanced contact materials) |

Indicates the duration of contact bouncing when opening or closing. Bounce can cause arcing and damage the contacts, so minimizing it ensures reliable switching. |

|

Electrical Parameters |

Pick - up Voltage |

20V DC (for a contactor in a 24V DC control system) |

The minimum voltage at which the coil energizes and the contacts close, ensuring proper response to control signals within the specified voltage range. |

|

Electrical Parameters |

Drop - out Voltage |

12V DC (corresponding to the above pick - up voltage) |

The maximum voltage at which the coil de - energizes and the contacts open, important for safe operation during power failures or abnormal conditions. It is usually lower than the pick - up voltage. |

|

Electrical Parameters |

Rated Insulation Voltage |

600V (suitable for general industrial environments) |

Evaluates the contactor's ability to withstand the maximum voltage between live parts and ground or different poles without breakdown, ensuring operator safety and system integrity. |

|

Mechanical Parameters |

Contact Travel |

4mm (for a common small - sized contactor) |

Measures the distance the contacts move during opening and closing operations. It affects the switching speed and reliability, and proper travel ensures good contact pressure and electrical connection. |

|

Mechanical Parameters |

Operating Force |

3N (designed for easy and reliable operation) |

Determines the force required to actuate the contactor's mechanism. It is related to the contactor's design and size, and an appropriate force range ensures smooth and reliable operation. |

In conclusion, a contactors testing bench is an invaluable tool for ensuring the reliable and efficient operation of contactors in various electrical applications. By accurately measuring and analyzing parameters such as coil resistance, contact resistance, pick-up and drop-out voltages, and mechanical characteristics, engineers can detect potential problems, optimize performance, and extend the lifespan of contactors. Regular testing using a contactors testing bench not only enhances the reliability of electrical systems but also contributes to the safety and productivity of industrial operations.