What Are You Looking For?

What Are You Looking For?

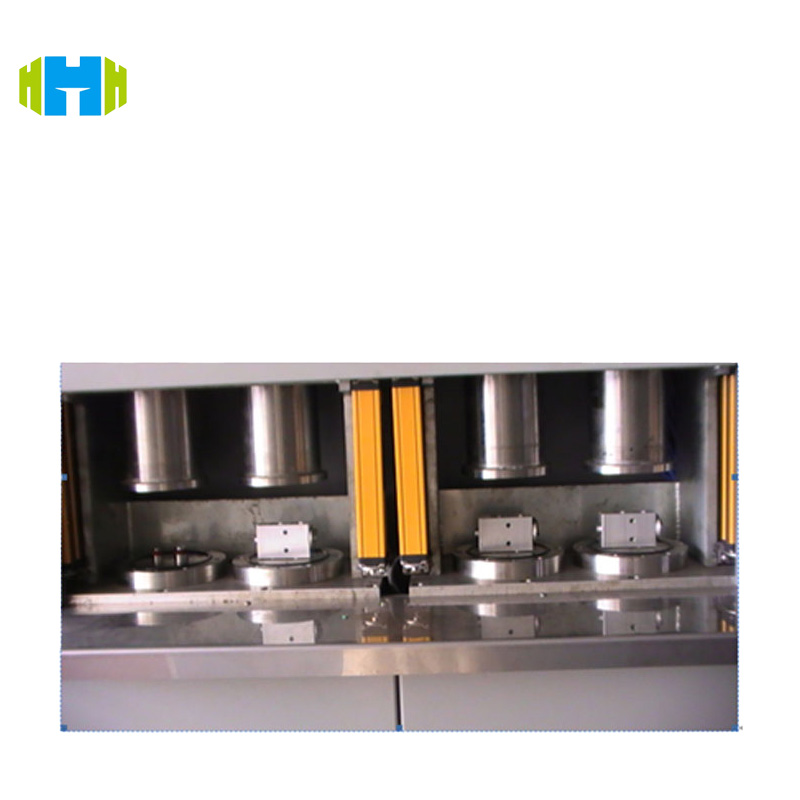

This vacuum box - type helium leak detection system is specifically designed by Guangzhou Hejin Automation Control Technology Co., Ltd. to detect leaks in automotive air - conditioning expansion valves. It offers high - precision detection with a series of technical features and quality guarantees.

Item No. :

HJ-APAT-001Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 sets per 2 monthLead Time :

60 Working DaysConventional packaging :

PlywoodThe system uses helium as a tracer gas. Based on the principle of helium leak detection, it can accurately identify whether the automotive air - conditioning expansion valve has leaks. The operation process is automated to a large extent, reducing human error and improving detection efficiency.

Technical Parameters:

|

Parameter |

Value |

|

Detected Workpiece |

Automotive air - conditioning expansion valve |

|

Number of Vacuum Boxes |

2 (each box for one workpiece) |

|

High - Pressure Gas for Large Leak Detection (Nitrogen/Compressed Air) |

2.0 MPa (adjustable downwards, e.g., can be adjusted to 1.5 MPa for specific needs) |

|

Tracer Leak Detection Gas |

Helium |

|

Alarm Leak Rate |

2 g/year |

|

Helium Pressure for Leak Indication |

1.7 MPa (adjustable downwards, such as 1.5 MPa for some tests) |

|

Production Cycle |

50 s/piece |

|

Helium Recovery |

Yes |

|

Number of Fixtures |

2 sets for one product |

|

Workpiece Loading/Unloading Mode |

Manual |

Large Leak Detection: After the vacuum box door is closed, the system first conducts rough and fine evacuation of the vacuum box until the set leak - detection pressure is reached. Meanwhile, 2.0 MPa (adjustable) high - pressure gas is filled into the workpiece. Then, it holds the pressure, and the pressure sensor checks for large leaks. If a large leak is detected, the high - pressure gas in the workpiece is discharged, the leak - detection process stops, and the vacuum box is filled with air. The operator can then remove the workpiece.

Vacuuming the Workpiece: If no large leak is found, the high - pressure gas in the workpiece is released, and the workpiece is evacuated until the set pressure value is reached.

Vacuum Helium Detection: When the vacuum box and the workpiece reach the set leak - detection pressure, the system suppresses the helium gas signal in the box to zero and then fills 1.7 MPa (adjustable) helium into the workpiece. The leak detector then checks for leaks. If the helium signal exceeds the set value, it indicates a small leak, and the system alarms. If not, the workpiece passes the test, and the helium recovery process starts.

Post - detection Process: After the detection is completed, the system automatically recovers the helium in the workpiece and fills the vacuum box with air. The operator can remove the workpiece according to the test result.

System Features:

Calibration Technology: The helium leak detector has an internal standard leak hole and can automatically calibrate its sensitivity and accuracy. There is also a standard leak hole for daily spot - checks to ensure system accuracy.

Ease of Operation: The system combines process automation and electrical control technology. Controlled by a PLC and a touch - screen, the operator only needs to load and unload the workpiece, and the system automatically judges and executes each process step.

Quality Assurance: The entire detection process is automated, reducing the impact of human factors. The system is composed of modular units, with core components imported to ensure high - precision and stable operation. It also has national - level metrological calibration to ensure the accuracy of leak detection.

System Composition:

The system consists of a vacuum box unit, a vacuum and leak - detection unit, and an electrical control unit. It is equipped with high - quality components from well - known domestic and foreign brands, such as BAOSI vacuum pumps, Agilent vacuum gauges and leak detectors, and OMRON PLCs, ensuring the overall reliability of the system.

Safety and After - sales:

Safety Assurance: The system has multiple safety measures, including pressure safety (qualified high - pressure containers with over - pressure safety valves and sensors), electrical safety (grounding and leakage protection), motor safety (current overload protection), and on - site safety (emergency stop switches, protective nets, and safety instructions).

After - sales Service: The system provides a 12 - month warranty starting 15 days after delivery. The manufacturer will replace parts due to quality problems (excluding consumables). There is at least one free annual inspection, and the maintenance response time is within 2 hours, with arrival at the customer's factory within 24 hours. The manufacturer also provides training and relevant technical documents.

Hot Tags :