What Are You Looking For?

What Are You Looking For?

The automobile double-chamber air spring helium tester launched by Guangzhou Hejin Automation Control Technology Co., Ltd. is a high-precision and high-efficiency testing equipment specially designed and developed for the air tightness testing of automobile double-chamber air springs.

Item No. :

HJ160-1Minimum Order Quantity (MOQ) :

1 SetPayment Method :

T/T,D/P,PaypalPrice :

NegotiatableProduct Origin :

TürkiyeSupply Ability :

One piece for three monthsLead Time :

90 working daysConventional packaging :

PlywoodAutomobile double-chamber air spring helium tester

Product introduction:

The automobile double-chamber air spring helium tester combines advanced helium testing technology with the concept of automatic control. It can accurately and quickly test the sealing performance of air springs during the production process of automobile parts, ensure that the product quality meets high standards, and effectively improve the safety and comfort of the car.

Product features:

(I) High-precision detection

Adopting advanced helium mass spectrometry leak detection technology, it has extremely high detection sensitivity and can detect extremely small leaks, ensuring that the air tightness of automobile double-chamber air springs meets strict quality standards, effectively avoiding the performance degradation or failure of air springs caused by small leaks, and ensuring the stability and safety of automobile driving.

(II) Dual-chamber independent detection

Specially designed for the structural characteristics of dual-chamber air springs, dual-chamber independent detection channels are designed. The two chambers can be tested simultaneously without interfering with each other, which not only improves the testing efficiency, but also accurately obtains the air tightness data of each chamber, provides more detailed and accurate information for product quality control, and helps to timely discover and solve the sealing problems that may exist in a single chamber.

(III) High degree of automation

The equipment has a highly automated testing process. From the loading, positioning, sealing connection, helium filling detection, helium recovery, data analysis to unloading of the air spring, the entire process is automatically completed by the PLC control system without excessive human intervention. The operator only needs to place the air spring to be tested in the specified position, and the equipment can automatically complete a series of testing operations and output a detailed test report, which greatly reduces the labor intensity of manual labor and improves production efficiency. At the same time, it reduces the impact of human factors on the test results and ensures the accuracy and consistency of the test.

(IV) Efficient helium recovery system

Equipped with an efficient helium recovery device, it can recycle and reuse the helium used in the test process, with a helium recovery rate of more than 95%. This not only reduces the cost of helium consumption, but also meets the requirements of environmental protection and energy conservation, reduces the waste of rare gas resources, and also reduces the production and operating costs of enterprises.

(V) Humanized operation interface

The equipment adopts an intuitive and simple human-computer interaction interface. Through touch screen operation, you can easily set detection parameters, start detection programs, view detection data and reports, etc. The operation interface has a multi-language switching function, which is convenient for users in different regions. At the same time, it also provides rich operation prompts and fault diagnosis information. Even non-professional technicians can quickly operate the equipment and perform daily detection work, and can promptly discover and solve problems that arise during the operation of the equipment.

(VI) Stable and reliable mechanical structure

The whole machine is made of high-quality steel, and after precision processing and strict assembly technology, it ensures that the equipment has a sturdy and durable mechanical structure. Key components such as sealing fixtures and pipe connections are made of high-quality sealing materials and connectors to ensure that the airtightness and stability of the equipment are not affected during long-term high-load operation, effectively reducing the failure rate of the equipment, and increasing the service life of the equipment, providing reliable protection for the production of the enterprise.

Technical standards:

This automotive double-chamber air spring helium tester strictly complies with the following relevant technical standards:

International standard: ISO 10156:2010 "Gases and gas mixtures for the determination of ignition hazard and oxidizing capacity for the selection of cylinder valve outlets"

National standard: GB/T 35544 - 2017 "Helium mass spectrometer leak detector"

Automotive industry standards: Industry standards

These standards can ensure that the quality and performance of the product meet the strict requirements of the domestic and foreign automotive industry for air spring air tightness testing equipment, and can provide reliable quality testing guarantees for automobile manufacturers, helping enterprises to produce high-quality, safe and reliable automotive products.

Technical parameters:

| Project | Parameters |

| Test workpiece | Automobile air spring |

| Gas for detecting large leaks | Nitrogen |

| Gas for detecting micro leaks | Helium |

| Number of vacuum boxes | 2 |

| Workpiece size | Designed according to actual size |

| Detection accuracy | 3x10-6Pa·m³/s |

| Large leak pressure | 0~2Mpa±0.02Mpa (adjustable) |

| Size | Length 3000mm*Width 4000mm*Height 3000mm |

| Weight | 2000kg |

Application area:

Automobile double-chamber air spring helium detector is mainly used in the automobile manufacturing industry, especially in the production of double-chamber air springs in automobile suspension systems.

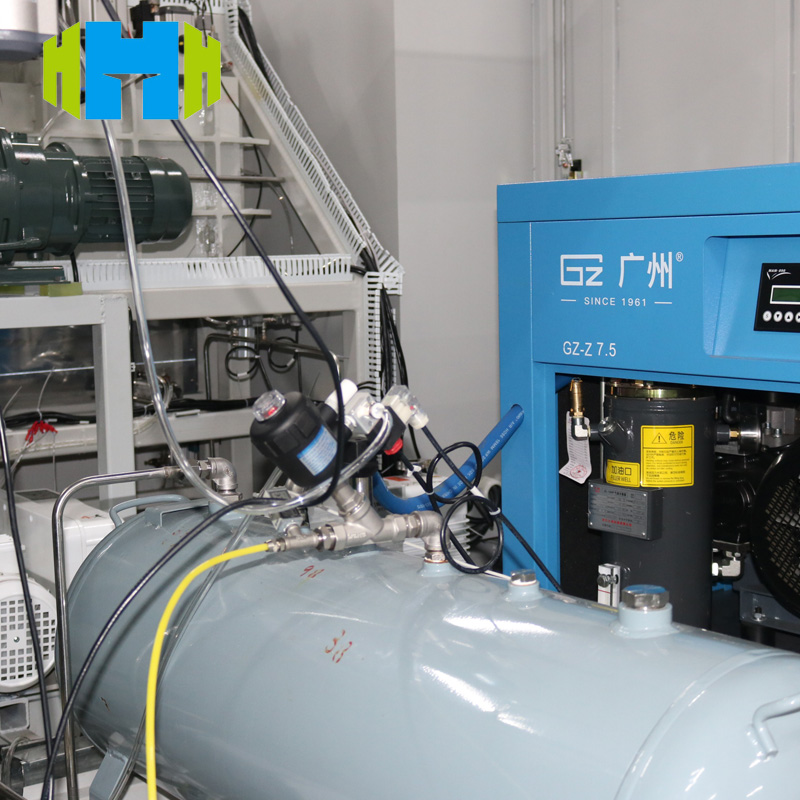

Detailed pictures:

FAQ (Frequently Asked Questions)

Q1: How to ensure the detection accuracy of the helium detector?

This helium detector uses a high-precision helium mass spectrometer leak detector as the core detection component, which has excellent detection sensitivity and stability.

Q2: Is the operation of the equipment complicated? Does it require professional training?

The operation of the equipment is relatively simple and convenient. We have designed a user-friendly operation interface, using a touch screen operation mode. All detection parameter settings, operation instructions, and detection data viewing functions are clear at a glance, and detailed operation guides and prompts are provided.

Q3: What is the working principle of the helium recovery system? What is the recovery rate?

The helium recovery system mainly works based on technical principles such as gas separation, compression, and purification.

The helium recovery rate of this equipment can be as high as 95% or more. The specific recovery rate will be affected by factors such as the detection process, equipment operating status, and helium use environment.

Q4: What aspects should be paid attention to in the maintenance of the equipment?

Equipment maintenance is crucial to ensure its long-term stable operation and detection accuracy. Daily maintenance work mainly includes the following aspects:

(1).Regularly check the airtightness of the equipment, especially the sealing fixtures, pipe connections and other parts. If there is a leak, the seal should be repaired or replaced in time.

(2).Regularly calibrate and maintain the helium mass spectrometer leak detector. According to the requirements of the instrument manual, regularly clean the ion source and replace the filament and other vulnerable parts to ensure the stable performance of the leak detector.

(3).Check the operating status of the helium recovery system, including the compressor, filter, storage tank and other components, regularly discharge impurities in the filter, check the lubricating oil level of the compressor and replenish or replace the lubricating oil in time.

(4).Keep the equipment clean and hygienic, regularly clean the dust and debris on the surface of the equipment to prevent dust from entering the equipment and affecting the normal operation of the electrical performance and mechanical components.

(5).Regularly check the electrical system of the equipment, including power cord, controller, sensor and other components, to ensure that the electrical connection is reliable and there is no looseness, short circuit and other abnormal conditions. If there is any problem, repair or replace the electrical components in time.

After-sales service:

Guangzhou Hejin Automation Control Technology Co., Ltd. is committed to providing customers with comprehensive, high-quality and efficient after-sales service to ensure that customers have no worries when using the automotive double-chamber air spring helium inspection machine.

1. Installation and commissioning service

After the equipment is delivered to the customer, our company will dispatch professional technicians to the customer site to install and commission the equipment.

2. Warranty service

The equipment provides a 1-year quality assurance period from the date of acceptance. During the warranty period, if there are any quality problems with the equipment, our company will provide free maintenance services, including replacement of faulty parts, repair of equipment control systems, etc.

3. Lifelong maintenance service

After the warranty period, our company will still provide customers with lifelong maintenance services. Customers can sign a maintenance agreement with our company. Our company will regularly inspect and maintain the equipment, and provide preferential maintenance services and spare parts supply.

4. Technical support service

Our company has a professional technical support team to provide customers with 7×24 hours of technical support services. If customers encounter any technical problems or questions during the use of the equipment, they can contact our technical support personnel at any time by phone, email, fax, etc., and the technical support personnel will provide customers with solutions and technical guidance in a timely manner.

In short, the automotive double-chamber air spring helium test machine produced by Guangzhou Hejin Automation Control Technology Co., Ltd. has become an ideal equipment choice for testing the air tightness of double-chamber air springs in the automotive manufacturing industry with its excellent product features, strict technical standards, advanced technical parameters, wide application fields and perfect after-sales service. We will always uphold the business philosophy of "quality first, customer first", provide customers with high-quality products and excellent services, and work hand in hand with customers to create a bright future for the automotive industry.

Hot Tags :