What Are You Looking For?

What Are You Looking For?

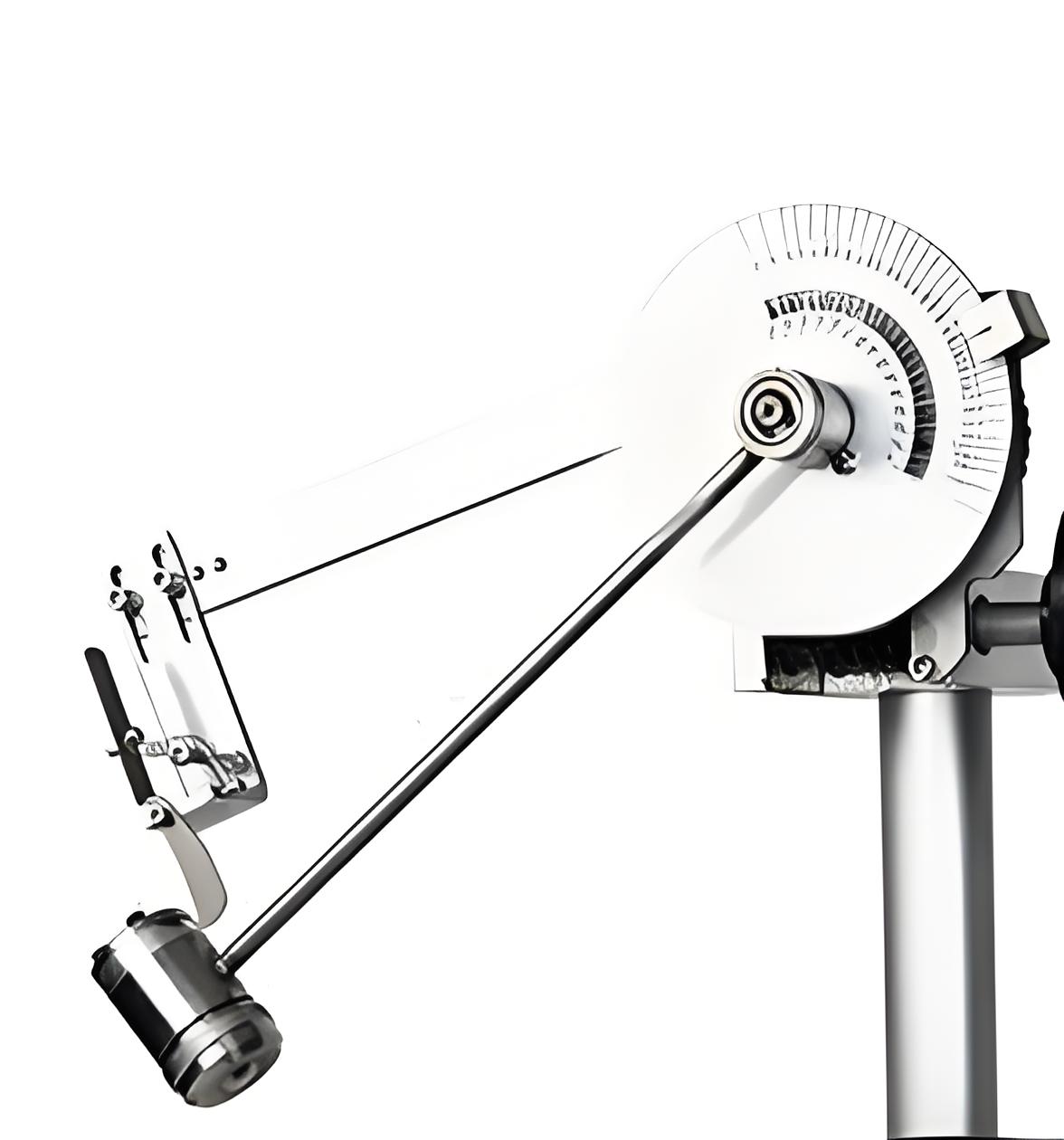

In the highly competitive landscape of industrial electrical equipment manufacturing, ensuring the robustness and durability of products is non-negotiable. The Pendulum Impact Testing Machine emerges as a pivotal tool in this pursuit, offering manufacturers an accurate and efficient means of evaluating the impact resistance of various components.

Item No. :

HJ-IEPTE-003Minimum Order Quantity (MOQ) :

1 setPayment Method :

L/C,T/T,PayPalPrice :

NegotiatableProduct Origin :

TurkiyeSupply Ability :

1 set per 2 monthLead Time :

60 Working DaysConventional packaging :

Plywood

The Pendulum Impact Testing Machine is engineered to simulate real-world impact scenarios that electrical products might encounter during their lifecycle, such as accidental drops, collisions, or mechanical shocks. It operates on the principle of converting gravitational potential energy of a pendulum into kinetic energy, which is then imparted onto the test specimen. This allows for a controlled and repeatable assessment of the specimen's ability to withstand sudden and intense forces.

Key Testing Parameters

|

Testing Parameter |

Value |

Significance |

|

Impact Energy |

Adjustable from 10 J to 500 J |

This wide range allows for testing everything from fragile smartphone casings to robust industrial gears. For example, a plastic toy might be tested at 20 J, while an automotive bumper could withstand 300 J, ensuring products of all kinds can have their impact resistance accurately evaluated. |

|

Pendulum Mass and Length |

Mass: 5 kg - 50 kg, Length: 1 m - 3 m |

A 10 kg pendulum with a 2 m length can simulate a moderate impact scenario like a falling tool in a workshop. On the other hand, a 40 kg pendulum with 3 m length can mimic a heavy impact in a construction site, enabling manufacturers to precisely replicate real-world forces. |

|

Impact Angle |

Adjustable from 0° to 90° |

Testing a laptop from a 30° angle can reveal vulnerabilities during accidental side impacts. Meanwhile, a 75° angle test on a window frame can assess its performance under extreme wind-borne debris impacts, providing crucial data for design improvements. |

|

Sample Fixture Design |

Compatible with specimens from 5 cm x 5 cm x 1 cm to 50 cm x 50 cm x 20 cm |

Whether it's a tiny circuit board or a large metal sheet for an aircraft wing, the fixture can hold it firmly. This means manufacturers across various industries, from electronics to aerospace, can rely on this system for accurate testing. |

The testing process commences with the careful preparation of the test specimen. The specimen is meticulously mounted onto the sample fixture, ensuring a snug fit and correct orientation. The desired impact energy, pendulum mass and length, and impact angle are then set according to the test requirements. Once all the parameters are configured, the pendulum is raised to the appropriate height, storing the required potential energy. Subsequently, the pendulum is released, and it swings down to strike the test specimen with the predetermined force. During the impact, high-speed cameras and sensors may be employed to capture the deformation and failure modes of the specimen. After the impact, the specimen is carefully examined for any signs of damage, cracks, or fractures. The test data, including the impact force, deformation measurements, and failure characteristics, are recorded and analyzed to determine the specimen's impact resistance performance.

Benefits of Using the Pendulum Impact Testing Machine

Enhanced Product Quality: By subjecting products to rigorous impact tests, manufacturers can identify and rectify potential design flaws or material weaknesses before the products reach the market. This significantly improves the overall quality and reliability of the electrical equipment, reducing the likelihood of failures during operation and enhancing customer satisfaction.

Compliance with Standards: The use of the Pendulum Impact Testing Machine enables manufacturers to ensure that their products comply with relevant industry standards and regulations regarding impact resistance. This is essential for market access and helps to build a reputation for producing high-quality and safe products.

Cost Savings: Early detection of product vulnerabilities through impact testing can prevent costly recalls, repairs, or replacements in the future. By optimizing the design and materials based on the test results, manufacturers can also reduce production costs by avoiding over-engineering or using inappropriate materials.

Design Optimization: The detailed data obtained from the testing machine provides valuable insights for engineers to optimize the design of the product. By understanding how different components respond to impact forces, they can make informed decisions about material selection, structural reinforcement, and geometric modifications, resulting in more robust and efficient designs.

In conclusion, the Pendulum Impact Testing Machine is an indispensable asset for industrial electrical equipment manufacturers. Its ability to accurately simulate and evaluate impact scenarios, combined with its versatile testing parameters and comprehensive benefits, makes it a must-have tool for ensuring the reliability and durability of products. Invest in this advanced testing equipment today and take your product quality to new heights, outshining the competition and winning the trust of your customers.

Hot Tags :